Product Description:

Ceramic laggings are becoming increasingly popular in the conveying

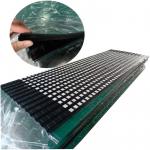

industry due to their durability and enhanced performance.What is Ceramic Pulley Laggings?

Ceramic pulley laggings are a type of lagging that is used to affix

conveyor pulleys. It is composed of a rubber matrix with embedded

ceramic tiles. Ceramic lagging is known for its superior durability

when compared to other types of lagging, such as rubber lagging. It

is typically used in high-wear applications in the mining, cement,

and material handling industries.

Benefits of Ceramic Lagging

Ceramic laggings provide a number of benefits for conveying

applications. The ceramic tiles offer more wear resistance,

hardness, and low friction than most other lagging materials, which

makes them ideal for harsh and abrasive conditions. The laggings

increase the frictional grip between the pulley and the conveyor

belt, resulting in improved belt traction, reduced slippage, and

better overall conveyor system efficiency.

Features:

- Product Name: Wear Lining Ceramic Pulley Lagging

- Thickness: 12mm, 15mm, 20mm, 25mm

- Shape: Square Ceramic

- Abrasion Resistance: High Abrasion Resistant

- Size: Customized

Technical Parameters:

Ceramics possess extreme hardness, with a Mohs rating of 9°. On the

other hand, rubber has a Shore A hardness rating of between 60 and

65. Both materials also different significantly in their tensile

strength, with ceramics having a value of 15MPa or higher and

rubber falling below this. Elongation at break is another important

property, where ceramics again outperform rubber with a value of

300% and higher, whilst rubber is around half this value.

Both materials have quite a wide temperature range, with ceramics

staying operational from -40℃ to 80℃. However, once again, ceramics

are the superior material in terms of wear resistance with an index

of 140 mm³ or lower, as opposed to rubber that falls well above

this. Finally, for peel strength, ceramics exceed rubber with a

value of 13MPa or higher, whist rubber is lower than this.

Applications:

Debon DB-TC ceramic pulley lagging is a wear solution for a variety

of applications, providing excellent protection from high abrasion

and impact. With a Mohs hardness rating of 9, its square ceramic

shape is highly resistant to wear and tear, and provides long-term

protection to pulleys and other surfaces. The ceramic pulley

lagging is available in both white and black colors, and can be

installed with either a CN bonding layer or cold bonding. It is

ideal for a variety of applications, such as belt conveyors, steel

plants, and other industrial applications, where wear lining

ceramic pulley lagging is required.

Debon DB-TC ceramic pulley lagging is designed with superior wear

resistance and abrasion resistance, making it an ideal choice for

protecting pulleys and other surfaces from wear and tear. Its

long-lasting protection and excellent performance in high-impact

applications make it the perfect wear lining solution for

industries such as steel plants, belt conveyors and other

industrial applications.

Debon DB-TC ceramic pulley lagging offers excellent protection from

abrasion and impact, and is available in both white and black

colors. It is easy to install with either a CN bonding layer or

cold bonding, and is ideal for a variety of applications where wear

lining ceramic pulley lagging is needed. With its superior wear

resistance and abrasion resistance, Debon DB-TC ceramic pulley

lagging is the perfect choice for protecting pulleys and other

surfaces from wear and tear.

Packing and Shipping:

The packaging and shipping of Ceramic Pulley Lagging should meet

the following requirements:

- The Ceramic Pulley Lagging should be packed in a wooden box with an

inner layer of foam or bubble wrap.

- The wooden box should be tightly sealed to protect the Ceramic

Pulley Lagging from moisture and dust.

- The package should be handled carefully to prevent any damage.

- The package should be shipped by a reliable carrier in a timely

manner.

FAQ:

- Q: What is Ceramic Pulley Lagging?

- A: Ceramic Pulley Lagging is a special friction coating applied to

a drive pulley to improve the traction of a conveyor belt. It is

manufactured by Debon (Model Number: DB-TC), with the place of

origin in JIAOZUO, HENAN, CHINA.

- Q: What are the benefits of Ceramic Pulley Lagging?

- A: Ceramic Pulley Lagging helps to reduce wear and tear on the

conveyor belt, improve belt tracking, reduce slippage, increase

efficiency, and reduce maintenance costs.

- Q: What type of pulleys can use Ceramic Pulley Lagging?

- A: Ceramic Pulley Lagging can be used on most types of drive

pulleys, including wing pulleys, drum pulleys, and snub pulleys.

- Q: How is Ceramic Pulley Lagging applied?

- A: Ceramic Pulley Lagging is typically applied by spraying or

rolling it onto the drive pulley. It is important to ensure that

the pulley is clean and free of any debris before applying Ceramic

Pulley Lagging.

- Q: How long does Ceramic Pulley Lagging last?

- A: The life expectancy of Ceramic Pulley Lagging depends on the

environment and usage, but it typically lasts for several years

before it needs to be replaced.