92% AI2O3 Alumina Ceramic Liner Chute Rubber Ceramic Liners For Mining

|

|

92% AI2O3 Alumina Ceramic Liner Chute Rubber Lining For Mining

Alumina Ceramic Liner Description:

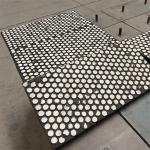

Alumina ceramic liner is a type of wear-resistant lining material used to protect industrial equipment from abrasion, impact, and corrosion. It is made of high-density alumina ceramic tiles or panels that are bonded to a substrate such as steel or rubber.

The alumina ceramic tiles are arranged in a specific pattern to provide maximum protection against wear and impact. They are known for their exceptional hardness and wear resistance, which make them ideal for use in harsh industrial environments.

Alumina ceramic liner is a durable and long-lasting solution for protecting equipment and reducing maintenance costs in challenging industrial environments. Alumina Ceramic Liner installed method:

Alumina Ceramic Liner selection chart:

Alumina Ceramic Liner Features:

1. High alumina ceramic offers excellent wear resistant 2. Rubber layer prevents ceramic tiles breakage 3. available with stud bolt and weldable installation methods or cn bonding layer 4. Various shape and size of ceramic, bricks, cylindrical, etc. 5. The magnets embedded in the rubber backing allow for quick and easy installation and removal of the ceramic tiles

Alumina Ceramic Liner Application:

Alumina Ceramic Liner Package:

Standard export packing, plywood pallet, no wood, no need fumigation Pallet size: 1000*1000*620mm, Pallet weight: 1.2 tons Pallet quantity for each 20GP container: 20~24 pallets Why choose us:

1. Ceramic wear liner manufacturer. 2. Reliable factory with extensive experience. 3. High quality and consistency 4. ISO9001, ISO45001, ISO14001 certified factory.

|

||||||||||||||||||||||||||||||||||||

| Product Tags: mining industrial ceramic lining pu backed mining industrial ceramic linings pu backed mining industrial ceramic liners pu backed |

|

99% Alumina ZTA Ceramic Wear Plate Lining Steel Backed |

|

Abrasion Resistant Alumina Ceramic Liner Tiles For Mining Cement |

|

95% High Alumina Ceramic Liner Rubber Ceramic Lining Steel Backing |

|

Circle 95% Alumina Ceramic Lining Wear Resistant ZTA Ceramic Tiles |

|

Hot Vulcanizing 99% Alumina Ceramic Liner Ceramic Wear Tiles |

|

Industrial Ceramic Chute Lining Polyurethane PU Magnet Backed Lining |