AI2O3 Ceramic Chute Liners Ball Mill Polyurethane Ceramic Tile Liners

|

|

Wear Ceramic Chute Liners Ball Mill Ceramic Tile Liners Polyurethane Ceramic Lining

Alumina Ceamic Liner Description:

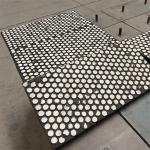

Alumina ceramic liner is a type of wear-resistant lining material used to protect industrial equipment from abrasion, impact, and corrosion. It is made of high-density alumina ceramic tiles or panels that are bonded to a substrate such as steel or rubber.

The alumina ceramic tiles are arranged in a specific pattern to provide maximum protection against wear and impact. They are known for their exceptional hardness and wear resistance, which make them ideal for use in harsh industrial environments.

Alumina Ceramic Liner Specification:

Alumina Ceramic Liner Features:

High wear and abrasion resistance Long wear life, low maintenance and downtime Significant noise reduction Available in awide variety of shapes and sizes Corrosion resistant Alumina Ceramic Liner Application:

Alumina ceramic wear liners are commonly used in industries such as mining, cement production, power generation, and steel manufacturing, where equipment is subjected to extreme conditions and heavy wear.

Alumina Ceramic Liner Package:

Standard export packing, plywood pallet, no wood, no need fumigation Pallet size: 1000*1000*620mm, Pallet weight: 1.2 tons Pallet quantity for each 20GP container: 20~24 pallets Why choose us:

1. Rich experience on production process of alumina ceramic liner 2. Strict quality control on ralumina ceramic liner 3. Good delivery time 4. Custom shape alumina ceramic liner are available. 5. Excellent bonding between rubber and ceramic

We are a factory dedicated to producing ceramic wear liner and have been improving the properties of ceramics. We use high quality rubber to offer better impact resistance and high quality rubber can also help holding the ceramic tiles, no ceramic tiles falling. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Ball Mill AI2O3 Ceramic Chute Liners AI2O3 Ceramic Polyurethane Ceramic Chute Liners AI2O3 Ball Mill Ceramic Chute Liners | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

99% Alumina ZTA Ceramic Wear Plate Lining Steel Backed |

|

Abrasion Resistant Alumina Ceramic Liner Tiles For Mining Cement |

|

95% High Alumina Ceramic Liner Rubber Ceramic Lining Steel Backing |

|

Circle 95% Alumina Ceramic Lining Wear Resistant ZTA Ceramic Tiles |

|

Hot Vulcanizing 99% Alumina Ceramic Liner Ceramic Wear Tiles |

|

Industrial Ceramic Chute Lining Polyurethane PU Magnet Backed Lining |