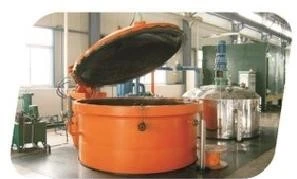

Transformers Vacuum Drying Oven With Casting Procss Of Epoxy Resin Used

|

Detailed Product Description

Basic Info.Model NO. KBB Material Status Solution, Strap Drying Medium Inactive Gas, Superheated Steam, Effluent Gas, Air Operation Pressure Vacuum Operational Method Continuous Turn-Key Projects One-Step Service Standard KCB Series Standard Product Name Vacuum Casting Equipment Pouring Pot Size mm 2200X3000 Mixing Bowl 300L Application Area for Electrical Insulators Transport Package Wooden Specification 900*900*900 Trademark JC Origin China HS Code 84292990 Production Capacity 60000PCS/Year Product DescriptionProduct Decription: KC Series of epoxy resin vacuum casting equipment is mainly used for dry-type transformers, dry-type casing, dry-type current transformers, dry-type transformers, high-voltage switch insulation, arc and other electrical products of epoxy resin casting production. 1 ,This series equipment used in electrical products with fillers and pouring; 2 ,This series equipment is suitable A Epoxy resins, UV-outdoor-type epoxy resin and polyurethane vacuum degassing, a combination of polymer materials and casting, for both foreign and domestic production of resin used. 3 ,This series of products can be used for user-filled hybrid and two-component mixed fillers, with great flexibility. 4 ,This series based on user demand, to increase or decrease the equipment system, modular Assembly option. Easy to install a high degree of automation and easy to master. KC Series casting equipment are: KCB Series standard vacuum casting equipment KCY Series of standard vacuum pressure casting equipment KCD Series of electronic measurement of vacuum pressure casting plant KCJ Series of static mixing vacuum pressure casting plant Main technical characteristics 1,The device from my company KBY Standard transformer vacuum drying equipment based on the latest research and rapid heating, more energy faster, vacuum drying equipment. 2,Device vacuum drying, vacuum, cryogenic condensation system, tran- sformer heating systems, pneumatic tube system, cooling system and co- ntrol system. 3,Vacuum, vacuum units selection of vacuum pump with the oil-water se- paration, and reduced operating costs. 4,Heating system transformer tank in stainless steel heating heating heating speed, automatically adjusting the velocity and temperature by temperature table size. 5,Condenser uses latest achievements in the world, horizontal condenser, stainless steel manufacture, recovery water automatic control. Configure chiller provides 10 degrees cold water system is installed below the condensation, ensure that the condensation effect. 6 ,Electric control system with touch-screen control, automatic control. 7,Compared with traditional vacuum drying and energy saving 50% Above.

is a high-tech private enterprise, it has a experienced term, which more than ten years engaged in research and development, design, manufacture and installation of vacuum equipment. Besides, it is not only committed to build high quality brand about vacuum equipment, but it also has prodcuts, which are widely used in impregnating, epoxy resin pouring, drying, and note oil processing in some industries(like metal heat treatment, transformer, and transformer device, reactor device, reg- ulator device, high pressure electrical, motor, capacitor, switch and other similar industries). Relying on strong technical advantages and scale advantages, and it also dedicated itslef to develop Vacuum application technology and relative vacuum equipment Main products are differnent kinds of vacuum casting equipments, vacuum drying equipment, vacuum impregnation equipment, vacuum oiling device equipment, and vacuum heat treatment equipment. The most important of this company is product qualitu, and it strictly follows international quality certification system, implmentcation od quality poliy about'creating a Kerry brands, buliding first-class equipment, following innovation for development, and being in accordance with customer service.It also provides the best solution, higher quality products and more valuable and efficient after-sales service for new and old customers.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Epoxy resin drying Oven transformers drying Oven Epoxy resin Vacuum drying Oven |

Related Products

|

1000X1000mm Clamp Plate Size Epoxy Resin 020 Bushing Machine For Heavy-Duty Applications |

|

PLC Control System APG Clamping Machine for Min Max Clamp Plate Strok |

|

250KN Clamping Force Electric Epoxy Resin Dispensing Machine |

|

Double-Station APG Clamping Machine for 10~35KV Current Transformer |

|

APG Process with Machine and APG mouls to Producing for Electrical Bushings |

|

Electric Power Source APG1210 Epoxy Resin Automatic Pressure Gel Hydraulic Molding Machine |

Email to this supplier