KUKA Robot KR16 R2010 MIG Welding Automatic Welding Robot With Megment Welder

|

|

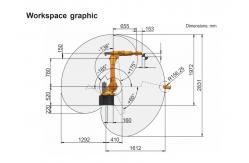

KUKA Robot KR16 R2010 MIG Welding Automatic Welding Robot With Megment Welder And CNGBS Welding Positioner Product Description:The KUKA KR16 R1610 robot offers several advantages for industrial automation. Its high payload capacity of up to 16kg and six-axis design provide flexibility and precision, allowing it to handle various applications such as material handling, pick-and-place, and assembly. The robot's compact design saves valuable floor space, making it an excellent choice for manufacturers looking to optimize their production lines. Its advanced motion control system ensures accuracy and repeatability, while its user-friendly programming interface makes it easy to integrate into production processes. The KR16 R1610's energy-efficient design reduces energy consumption and operating costs, while its durable and reliable construction ensures long-term performance with minimal maintenance. Overall, the KUKA KR16 R1610 is an excellent choice for industrial automation, offering high performance, flexibility, and efficiency to enhance production processes. Features:The KUKA KR16 R1610 is an extremely versatile and reliable robot for industrial automation. It has a impressive payload of up to 16kg and a six-axis design for enhanced flexibility and precision, making it suited for countless applications such as material handling, pick-and-place, and assembly. In terms of size, the KR16 R1610 has a compact design to save valuable floor space. Also, its advanced motion control system makes sure accuracy and repeatability are always produced. Safety is enhanced with the patented SafeOperation technology. Furthermore, its energy-efficient design reduces energy consumption and operating costs. The robot also has a very durable and reliable construction that offers longevity with minimal maintenance required, besides its user-friendly programming interface makes production process easier to integrate. In short, the KUKA KR16 R1610 robot offers high performance, flexibility, and efficiency that will surely enhance production processes. Technical Parameters:

Applications:The KUKA KR16 R1610 is designed to be perfect for a variety of industrial applications, due to its high payload capacity and six-axis design. It allows precision and flexibility for different tasks and allows for material handling, pick-and-place, and assembly tasks. Due to its advanced motion control system, accuracy and repeatability is guaranteed. The KR16 R1610 also boasts a great many convenient features. Its compact design allows for flexible production processes, combined with a user-friendly programming interface, ensuring a straightforward integration into any production pipeline. Additionally, the robot features KUKA's SafeOperation technology, providing safe and dependable operation. Furthermore, thanks to its energy-efficient design, the KR16 R1610 also greatly reduces energy consumption and operating costs. To sum it up, the KUKA KR16 R1610 is an all-rounder for industrial automation applications, providing a solid combination of reliability, performance, efficiency, and flexibility. As such, it is the ideal choice for production processes that call for precision and efficiency. Support and Services:Welding Robot Arm Technical Support and Service We provide comprehensive technical support and service for our Welding Robot Arm products. Our experienced technicians are available to answer any questions about the product and can provide assistance in troubleshooting any problems that may arise. We also offer a range of spare parts and upgrades for our Welding Robot Arms, and our team is always available to provide advice and guidance on any repairs or modifications needed. We provide fast and reliable customer service, and our team is dedicated to ensuring that each customer receives the highest level of care and satisfaction. We strive to provide the best possible experience for our customers and are committed to providing quality products and services. Packing and Shipping:Packaging and Shipping for Welding Robot Arm Welding robot arms are carefully packaged for the best protection during delivery. They are shipped in customized wooden crates with shock-proof foam inserts. Each crate is secured with 2-inch wide steel bands and sealed with adhesive tape for extra protection. The crates are further secured with plastic wrap and placed on a pallet for improved sturdiness. The crates are shipped via ground or air freight depending on customer’s location. All freight charges, duties, and taxes are prepaid by the seller. ``` About Us: Xiangjing (Shanghai) Mechanical and Electrical Tech Co., Ltd. is

thesubcompany of Dr. Industry Group Co, Ltd. that was founded

inJanuary 2015.

FAQ:

Q.How long will you need before delivery?

|

||||||||||||||||||||

| Product Tags: KR16 kuka spot welding robot R2010 kuka spot welding robot ip65 kuka arc welding robot |

|

Yaskawa AR1440 Customizable 6 Axis arc Welding Automation robotic Arm with Megmeet welding machine welder and TBI welding gun With 380-480VAC Power Requirements |

|

Kuka Robot Arm KR 10 R1420 With CNGBS Welding Positioner And Megmeet Welder For Robotic Welding Solutions |

|

AR2010 12kg Payload Welding Robot Arm 380-480 VAC YASKAWA Industrial Robot Arm |

|

6 Axis Payload 6kg Reach 1427mm OTC FD-V6S Welding Robot Arm With AOTAI Welder And TBI GUN For Welding Materials |

|

Kuka Welding Robot Arm With OTC Arc Welding Machine Tbi Welding Torch |

|

6 Axis Welding Robot Arm ABB Brand IRB 1520ID Welding Robot With Megmeet Welding Power And Positioner |