HDPE Coated PVDF ACP Sheets 4.0mm Thickness For Hotel Interiors

|

|

HDPE Coated PVDF ACP Sheets - 0.1mm Aluminum Layer, 4.0mm

Thickness, Special Effects Surface for Hotel Interiors

Aluminum Composite Panel (ACP), commonly referred to as aluminum plastic board, is a type of flat panel consisting of two thin aluminum sheets bonded to a non-aluminum core. It is widely used in building exteriors, interior decorations, and signage due to its lightweight, durability, and versatility. The core material is often made of polyethylene or other fire-resistant materials, providing structural stability and thermal insulation. ACPs are popular for their aesthetic appeal, available in various colors, finishes, and patterns, including mirror, brushed, and wood grain surfaces. This combination of features makes ACP ideal for applications like cladding, facades, partitions, and advertising panels.

Our company—— Since our establishment in 1999, we have learned and integrated both local and advanced continuous extrusion thermal composite panel technologies. With years of production expertise and operational experience, we have built a highly skilled team that has mastered the production of high-quality aluminum composite panels. These panels are widely used in various applications, ranging from exterior wall decoration to mechanical casings and other decorative items. Our commitment to quality has made our products renowned for their durability, aesthetics, and functionality, earning them the title of a favorite in contemporary design. We take global standards seriously and are proud of our certifications, including A2-grade fire resistance, B1-grade flame retardance, and the honor of being recognized as a 'China Famous Brand.' Under our brand 'Richly Bound,' we produce a wide range of aluminum composite panels. Our panels meet national standards, and our production capacity is unmatched. Our factory is conveniently located about 200 kilometers from Hong Kong and Macau, offering easy access to transportation and freight. We welcome global clients for cooperation.

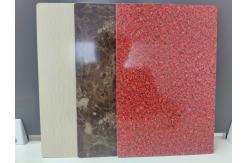

What you can purchase We also offer a variety of colors for you to choose:

Why is ACP?

Product processing performance

Our aluminum composite panels can be easily processed using both woodworking and metalworking tools, allowing for various operations such as cutting, sectioning, milling, perforating, compressing, folding, and bending. This enables precise fulfillment of architectural decorative needs, including designs like curves, reverse curves, small-radius bends, and both internal and external angles. Such versatility is uncommon in other decorative materials.

Our production line Illustration of on-site construction and installation methods |

| Product Tags: HDPE Coated PVDF ACP Sheets PVDF ACP Sheets 4.0mm Thickness |

|

PVDF ACP Sheets With Wood Grain Finish 2.0mm Thickness 0.18mm Aluminum Layer For Lounge Interiors |

|

PVDF ACP Sheets For Showroom Wall Cladding 3.0mm Thickness High Gloss Surface 0.25mm Aluminum Layer |

|

PVDF ACP Sheets With Mirror Finish 5.0mm Thickness 0.3mm Aluminum Layer Custom Size For Office Ceilings |

|

Lightweight PVDF ACP Sheets For School Partitions 4.0mm Thickness Anodized Coating Solid Color |

|

HDPE Coated PVDF ACP Sheets 6.0mm Thickness Special Effects Surface 0.15mm Aluminum Layer For Hotel Interiors |

|

PVDF ACP Sheets With Stone Grain Surface 3.0mm Thickness 0.1mm Aluminum Layer For Café Counters |