Stencil Cleaning Machine - Visualization Process & Stainless

Steel BodyTW-1600S

This equipment is suitable for cleaning various types of

screen plates such as wire mesh, steel mesh, copper mesh, rubber

mesh, microporous mesh, etc. The equipment uses pure compressed air

to drive the diaphragm pump, allowing the cleaning solution to be

recycled inside the machine, achieving zero discharge of the

cleaning agent.

The working principle of the equipment is to drive a

pneumatic diaphragm pump with compressed air. After the cleaning

liquid is pressurized by the diaphragm pump, it is sprayed onto the

screen by the nozzle rotation. After cleaning is completed, it is

blown dry with compressed air, ultimately achieving the effect of

cleaning and drying the screen.

The cleaning effect of the equipment is stable, efficient,

and time-saving.

Equipment features:

1.Visualization of cleaning process;

2.All stainless steel body: beautiful, wear-resistant,

corrosion-resistant, in compliance with environmental requirements

and standards;

3.Fully pneumatic operation, no electricity, no safety hazards such

as fire, and has passed EU safety certification;

4.High density equal pressure dual side rotating cleaning nozzle:

strong cleaning force without damaging the tension of the steel

mesh;

5.Three stage filtration system and low exhaust duct design:

solvent recycling, low liquid consumption;

6.System integration Global high-quality devices: ensure excellent

quality, stable performance and long service life.

Working principle:

Feeding---Cleaning agent pressure filtration---High speed rotating

spray---Compressed air rotary drying---blanking.

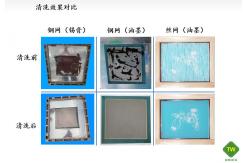

Comparison of cleaning effects:

Technical Parameter:

| Applicable steel mesh size: | L750 X W750 X H40 (mm) | Compressed air: | 0.45~0.7 Mpa | | Maximum volume of liquid tank: | 42L | Gas consumption: | 350~500L/min | | Optimal liquid usage: | 22-35L | Exhaust port size: | Φ100 X 30 (mm) | | Cleaning/drying method: | 360 degree rotating spray cleaning/compressed air drying | Filtration system: | Three stage filtration (up to 0.45um filter element) | | clean time: | 3-5 minutes | machine net weight: | Approximately 230 KG | | drying time: | 3-5 minutes | Machine dimensions: | L950 X W800 X H1680 (mm) |

FAQ:. - What is the power supply required for the equipment?

- This model does not require a power supply and uses a compressed

air source.

- What are the dimensions of the equipment?

- The equipment size is L950 X W800 X H1680 (mm).

- Is the equipment environmentally friendly?

- Yes, the equipment is environmentally friendly, with low energy

consumption, low operating noise, and no pollution. It also meets

the ROHS and halogen-free requirements of the electronics industry.

- What are the main features of the equipment?

- This equipment is suitable for the cleaning of various types of

stencils such as silk screen, stencil, copper mesh, rubber mesh,

microporous mesh and so on. The equipment adopts pure compressed

air to drive the diaphragm pump, so that the cleaning liquid is

circulated inside the machine, which can achieve zero emission of

cleaning agent.

- What industries can the product be used in?

- The product can be used for daily cleaning of highly reliable

products in military, instrumentation, communication, industrial,

and semiconductor industries.

|