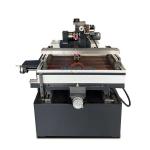

Fast Speed CNC Wire Edm Cutting Machine DK7735 For Metal Processing

|

|

Advantages of the DK7735F EDM Wire Cutting Machine1. High-Precision Machining CapabilityThe EDM wire cutting technology (Wire EDM) can achieve extremely high machining accuracy, typically reaching micron-level tolerances. This makes it ideal for manufacturing complex parts with strict dimensional requirements, especially in aerospace, medical devices, and precision mold manufacturing. 2. Ability to Machine Complex ShapesThe DK7735F wire cutting machine can process complex geometries that are difficult to achieve with traditional machining methods, including fine contours, sharp corners, and intricate internal structures. It uses high-frequency electrical discharge to precisely erode materials, meeting high-difficulty design demands. 3. Suitable for Hard Material ProcessingEDM wire cutting is not limited by the hardness of the workpiece and can machine hardened steel, cemented carbide, and other high-hardness materials that are typically challenging for conventional cutting methods. The DK7735F is especially suitable for manufacturing wear-resistant molds and tools. 4. Stable Machine Structure and Easy OperationThe DK7735F adopts resin sand casting technology, combined with mechanical analysis design and optimized support rib arrangement, ensuring strong load-bearing capacity and overall operational stability. Additionally, its wire threading operation is simple, with particularly convenient wire tightening, improving work efficiency and reliability. 5. Automation and High EfficiencyModern EDM wire cutting machines are usually equipped with automatic wire threading and precise wire guiding systems, enabling efficient and continuous machining processes with reduced manual intervention and downtime. The DK7735F performs well in these aspects, suitable for producing small batches and complex parts. 6. Suitable for Small Batch and Rapid PrototypingBecause EDM wire cutting does not require expensive tooling preparation, it is ideal for small batch production and rapid prototyping. The DK7735F is flexible enough to meet various customized needs, shortening product development cycles. In summary, the DK7735F EDM wire cutting machine offers advantages such as high-precision machining, the ability to cut complex shapes, suitability for hard material processing, a stable and easy-to-operate machine structure, high automation and efficiency, and flexibility for small batch and rapid prototyping. These features make it widely valuable in mold manufacturing and precision parts processing industries.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: DK7735 Wire Edm Cutting Machine CNC Wire Edm Cutting Machine Metal Processing Wire Edm Cutting Machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Fast Speed Wire Edm Cutting Machine DK7745 For Metal |

|

Fast Speed Wire Edm Cutting Machine DK77 Series CNC For Metal Parts |

|

High Speed Edm Cutting Machine Metal Processing 1720x1680x1700mm |

|

Wire Cutting Cnc Machine Edm DK7750F Fast Speed Metal Processing Machine |

|

DK7745F Cnc Wire Edm Machine Cutting Fast Speed Metap Processing Machine |

|

Stainless Steel Aluminum Wire Electrical Discharge Machine F Type |