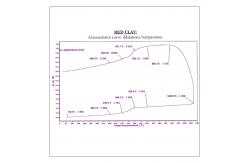

Clay Analysis Curve Diagram Chemical Analysis Lab For Brick Making Raw Material

|

|

BRICTEC Brick Raw Material Analysis Service for Composition Analysing and Testing

Xi'an Brictec Engineering Co., Ltd. provides a series of brick factory services including: raw material analysis, design and guidance, accessories supply, upgrade and improvement, production management, etc.. Among them, raw material analysis helps to understand clients' raw material conditions clearly, providing clients with more professional and accurate brick making solutions.

Raw material analysis includes 7 parts: 1. Raw material physical properties 2. Raw material chemical properties 3. Drying properties 4. Firing properties 5. Lime bursting test 6. Frosting test 7. Conclusion and suggestion

Sample Display

1. Raw material physical properties

2. Raw material chemical properties

3. Drying properties The shaped samples are dried naturally for 24 hours and then put into the oven at 105±5℃ for 8 hours. There were no cracks on the dried brick samples, and the strength is quite good, and drying line shrinkage ratio is 1.76%. 4. Firing properties

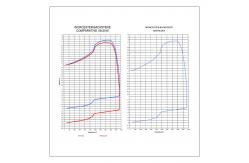

(1) Temperature gradient furnace: small samples (40x20x10mm) is fired in the temperature gradient furnace to measure the firing temperature and temperature range. Firing conditions is as follow: Heating rate: <200℃/hr Figure 1 Small-sized sintered bricks burned in temperature gradient furnace from 900℃~1150℃ (2) Product firing shrinkage rate and water absorption rate: firing shrinkage rate and water absorption rate are measured on the samples fired in the gradient furnace, and the relationship curves among temperature, water absorption and shrinkage are shown in Fig. 2.

The sample firing system is listed below (table 1) by combing

figure 2 (firing curve) and sample firing condition at different

temperature.

(3) High temperature firing furnace: the dried samples were fired

in the high temperature furnace according to the regular firing

system. Firing conditions were as follow: Clay samples: small-scale experimental sintered brick sample fired

at 1040℃ 5. Lime bursting test The test was carried out on fired samples, and there was no lime bursting phenomenon occurred in the small-scale simulated test. 6. Frosting test The test was carried out on fired samples, and there was no frosting phenomenon occurred in the small-scale simulated test. 7. Conclusion and suggestion (1) Sample clay has higher content of CaO, low plasticity and low

drying sensitivity. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Clay material analysis testing material analysis testing chemical analysis lab For Brick | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Automatic Hammer Crusher for Clay Brick Raw Materials Energy Saving ISO Certified |

|

Durable Chain Plate Box Feeder Specialized in Clay Sintered Brick Manufacturing Process |

|

High Capacity Belt Type Box Feeder with Adjustable Speed for Brick Making Plant |

|

Customizable Rotary Screen Feeder for Your Specific Requirements |

|

Automatic Bridge-Type Bucket Reclaimer Enclosed Design for Clay Brick Raw Material Storage |

|

Heavy Duty Dual-Roller Clay Crusher - German Technology for Brick Raw Material Preparation |