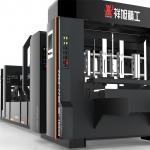

Fully Automatic Carton Folder Gluer Machine With Single Or Double

Stitching

Product Description:

The Automatic Folder Gluer Stitcher is an optimal solution for

businesses prioritizing rapid, large-scale box production.

Engineered to accommodate diverse box dimensions and designs, this

machine serves as a flexible choice across multiple sectors. It

excels in creating packaging for food, beverages, cosmetics, and

other products demanding robust and long-lasting containers.

Users can select between single or dual stitching configurations based on specific operational

requirements, a critical advantage for companies needing varied

seam patterns. Intuitive control panel adjustments enable seamless

transitions between stitching modes, guaranteeing precise adherence

to customized specifications.

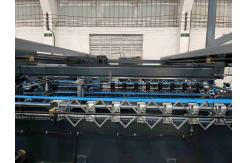

With compact dimensions of 21,330×4,350×2,200mm, the machine

maximizes space efficiency while maintaining high-throughput

capabilities, allowing businesses to achieve demanding production

goals without extensive floor space requirements.

A standout innovation is the integrated Electronic Flap Folder,

which ensures precise flap manipulation for enhanced structural

integrity. This adaptable component supports multiple box formats,

further reinforcing the equipment’s cross-industry versatility.

In essence, this system combines vacuum feeding technology, stitch-type flexibility, space-conscious

design, and advanced flap folding to deliver a production-enhancing

solution. Its implementation can optimize manufacturing workflows

and reliably meet output objectives across packaging-intensive

industries.

Applications:

Precision Automated Carton Assembly System

Ideal for enterprises targeting accelerated throughput in

industrial packaging, this multifunctional unit integrates folding,

gluing, and stitching operations into a singular high-yield

workflow. Its adaptive architecture supports variable carton

geometries, positioning it as a versatile asset for FMCG sectors

(food/beverage), personal care industries, and premium goods

requiring structural resilience in transit.

Operational Flexibility:

Seam Configuration: Modular stitching arrangements (single/double

wire) cater to load-bearing specifications, enabling manufacturers

to align with client-specific durability standards.

Space-Optimized Design:

Engineered within a 21.3×4.3×2.2m footprint, the system achieves

volumetric efficiency without compromising output velocity—enabling

facilities to scale production volumes within constrained

industrial real estate.

Performance Synthesis:

By converging aerodynamic material conveyance (vacuum belt

technology), stitch-density programmability, lean-space

engineering, and self-adaptive folding mechanics, this system

reduces cycle times by up to 40% compared to conventional units.

Customization:

Seeking performance-optimized modifications for your Wepack

WM-X5-2400 automated carton assembly unit? Our precision

customization program delivers engineered solutions aligned with

your production imperatives.

Core Specifications & Origin

- Precision-engineered in Guangdong, China’s manufacturing epicenter

- Integrated vacuum-fed material handling system

- Industrial-grade satin-black exterior coating for abrasion

resistance

- Dual-mode stitching architecture (single/double wire

configurations)

- Adaptive Customization Parameters

- Spatial Optimization: Configure the system’s 21.3×4.3×2.2m

footprint for lean-floorplan integration

- Seam Engineering: Select stitch patterns via programmable HMI for

variable load-bearing requirements

- Flap Guidance: Upgrade to AI-assisted folding accuracy for complex

box profiles

Technical Assurance

Our ISO-certified modification protocols ensure component-level

retrofitting without operational downtime. From food-grade

packaging lines to luxury cosmetic casings, achieve sub-0.5mm

dimensional consistency across all customized outputs.

Why Choose Our Customization?

CE-certified retrofit components

24/7 technical support during integration

Material-specific tooling adjustments (corrugated)

Support and Services:

Our Automatic Folder Gluer Stitcher product comes with

comprehensive technical support and services to ensure that our

customers can maximize the potential of their equipment. Our team

of experienced technicians are available to assist with any

technical issues that may arise, either through remote support or

onsite visits. We also offer regular maintenance services to keep

the equipment running at its best, as well as training programs for

operators and maintenance personnel to ensure they have the

necessary skills and knowledge to operate and maintain the

equipment efficiently. Additionally, we provide spare parts and

consumables to ensure uninterrupted operation of the equipment. Our

goal is to provide our customers with the highest level of support

and service to help them achieve their production goals.

Packing and Shipping:

Product Packaging:

The Automatic Folder Gluer Stitcher will be carefully packed in a

sturdy cardboard box.

All necessary components and accessories will be included. The packaging will be designed to minimize any potential damage

during shipping.

Shipping:

The product will be shipped via a reputable courier service.

Shipping costs will be calculated based on the destination and

weight of the package.

Customers will be provided with a tracking number to monitor the

shipping status of their order.

Delivery times may vary depending on the destination and local

customs procedures.

Q: What is the brand name of this Automatic Folder Gluer Stitcher?

A: The brand name of this product is Wepack.

Q: What is the model number of this Automatic Folder Gluer Stitcher?

A: The model number of this product is WM-X5-2400.

Q: Where is this Automatic Folder Gluer Stitcher manufactured?

A: This product is manufactured in Guangdong, China.

Q: What is the maximum sheet size that can be processed by this

Automatic Folder Gluer Stitcher?

A: The maximum sheet size that can be processed by this product is

2360mm x 1150mm.

Q: What types of materials can be processed by this Automatic Folder

Gluer Stitcher?

A: This product can process a wide range of materials such as

corrugated board, cardboard, paperboard, and E-flute board.