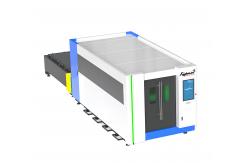

Metal Sheet Laser Cutting Machine with Exchangeable Table and CYPCUT Control Software

|

|

Shanghai Raylaser Enclosed Pallet Changer Series: Uninterrupted Production for Demanding Workshops Experience continuous laser cutting operations with Shanghai Raylaser’s Fully Enclosed Pallet Changer Systems – engineered for high-volume production in the USA, Saudi Arabia, and global industrial hubs. Our enclosed table laser cutters combine robust fiber laser technology (1kW-60kW) with automated material handling, maximizing uptime while ensuring operator safety and precision cutting of steel, aluminum, and reflective metals. Key Features & Technical Advantages:

Technical Specifications (Enclosed Series):

Standard Config: MAX/Raycus laser source • S&G chiller • 380V/3-phase power Hermetic enclosure protects optics from sand/sediment (critical for Middle East operations)

FAQs: Enclosed Pallet Changer Systems Q: How does enclosed design improve safety vs open machines? Q: What maintenance does the pallet system require? Q: Can I retrofit existing Raylaser machines? Q: How does pallet changing impact productivity?

Q: What shipping protection do you provide?

Global Support Infrastructure

Why Industry Leaders Choose Raylaser:

|

||||||||||||||||||||||||

| Product Tags: cypcut software laser cutting machine cypcut metal fiber laser cutting machine exchangeable table laser cutting machine |

|

Customized Design Fiber Laser Tube Cutting Machine Laser Wavelength 1064nm For Advanced Cutting |

|

Metal Enclosed Laser Cutting Machine With Cypcut Control System And Raytools Laser Head Durable |

|

Metal Manufacturing High Power Fiber Laser Cutting Machine With 1064nm Wavelength |

|

CNC Laser Cutting Machine 6000W 8000W 20KW 30KW For Carbon Steel Stainless 30mm 50mm |

|

CYPCUT Enclosed Laser Cutting Machine with 6.56 Feet X 13.12 Feet Working Area |

|

Fiber Aluminum Laser Cutting Machine 4020 Cutting Speed 0-100m/Min |