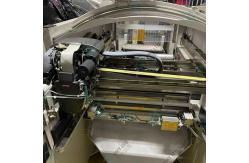

SMT Siemens F5HM Pick and Place Machine

|

Title: Maximizing Efficiency in Electronics Manufacturing with the Siemens F5HM Pick and Place MachineThe Siemens F5HM Pick and Place Machine is a cornerstone of modern surface mount technology (SMT) assembly lines, renowned for its precision and efficiency. This article delves into the features, advantages, and applications of the Siemens F5HM Machine, illustrating how it revolutionizes the manufacturing process in various industries. --- Introduction to the Siemens F5HM MachineThe Siemens F5HM Machine is designed to meet the increasing demands of electronics manufacturing. With its advanced technology, it offers unparalleled speed and accuracy in component placement, making it an essential tool for manufacturers looking to enhance their production capabilities. --- Key Features of the Siemens F5HM Pick and Place Machine1. High-Speed Performance- Placement Speed: The F5HM can achieve a speed of up to 1800 components per hour (CPH), ensuring rapid production cycles. - Efficiency: Designed for high-volume production, it minimizes downtime and maximizes throughput. 2. Advanced Placement Heads- Nozzle Configuration: The machine is equipped with either a 12-nozzle or a 6-nozzle collection placement head, allowing for versatile handling of different component sizes. - IC Head Capability: The inclusion of an integrated IC head enhances its ability to place integrated circuits with precision. 3. Superior Accuracy- Placement Accuracy: Achieves an impressive accuracy of ±70µm at 4 sigma, ensuring components are placed exactly where needed. - Real-Time Monitoring: The machine features real-time monitoring systems that help maintain quality control throughout the production process. 4. Flexible Component Handling- The Siemens F5HM can handle a wide range of components, from small chip resistors to larger integrated circuits, making it suitable for various applications. 5. User-Friendly Interface- The intuitive software interface simplifies operation and setup, reducing training time for new operators and enhancing overall productivity. --- Benefits of Using the Siemens F5HM Machine1. Increased ProductivityThe high-speed capabilities of the Siemens F5HM allow manufacturers to increase their output significantly without sacrificing quality. 2. Cost EfficiencyBy reducing errors and rework through precise placement, the F5HM helps lower production costs, making it a cost-effective solution for manufacturers. 3. VersatilityIts ability to handle different types of components makes it adaptable to various production needs, from prototyping to mass production. 4. Enhanced Quality ControlWith real-time monitoring and feedback systems, manufacturers can ensure consistent quality in their products. --- Applications of the Siemens F5HM Pick and Place MachineElectronics ManufacturingThe Siemens F5HM is widely utilized in the electronics industry for assembling devices such as smartphones, tablets, and consumer electronics. Automotive IndustryIn automotive manufacturing, the F5HM plays a crucial role in producing circuit boards for various electronic components used in vehicles. TelecommunicationsThe machine is essential for assembling high-density PCBs found in communication devices like routers and modems. ConclusionThe Siemens F5HM Pick and Place Machine stands out as a leader in SMT technology due to its exceptional speed, accuracy, and versatility. As industries continue to evolve towards more automated solutions, machines like the F5HM will play a crucial role in shaping the future of manufacturing. --- Frequently Asked Questions (FAQs)Q1: What is the maximum speed of the Siemens F5HM Machine?- The maximum speed is up to 1800 components per hour (CPH). Q2: What types of components can the F5HM handle?- It can handle a wide range of components from small chip resistors to larger integrated circuits. Q3: How accurate is component placement with the Siemens F5HM?- The placement accuracy is ±70µm at 4 sigma. Q4: Is the Siemens F5HM suitable for low-volume production?- Yes, its versatility allows it to be used effectively for both low-volume and high-volume production runs. Q5: What industries benefit from using the Siemens F5HM?- It is widely used in electronics manufacturing, automotive industry, and telecommunications.

SMT Siemens F5HM Pick and Place Machine | GSSMT, Siemens F5HM Machine, High-Speed Pick and Place, SMT Placement Technology, Precision PCB Assembly, Automated Component Placement, Advanced Feeder Systems, Electronics Manufacturing Solutions, Modular SMT Equipment, Component Mounting Accuracy, Flexible PCB Handling, High-Performance SMT Machines, Digital Vision Systems, Industry 4.0 Automation, Multi-Head Placement Technology, Efficient Production Lines, Component Range Specifications, Real-Time Quality Control, Cost-Effective Manufacturing Solutions, User-Friendly Interface, High-Volume Production Systems |

| Product Tags: F5HM Pick and Place Machine Siemens Pick and Place Machine |

|

SMT Setting machine 2800*2000*1800mm |

|

Vacuum Reflow Soldering Machine Customizable |

|

Material Frame Vertical Hot Air Curing Oven 67KW |

|

SMT Pick And Place Machines Full Automatic Solder Paste Printer KEYAN-K6 |

|

SMT Pick And Place Machines Full Automatic Solder Paste Printer KEYAN-K3 |

|

RX-7R Compact Speed SMT Pick And Place Machine For Fast Assembly Mass 820kg Operating Air Pressure 0.5±0.05MPa |