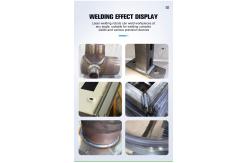

Minimal Downtime Robotic Welding equipment Adaptability to Various

Welding Type

Product characteristics: Reduced Material Waste: Robots use precise amounts of welding material, reducing waste

and lowering material costs over time. Lower Labor Costs: Automating welding processes reduces the need for manual labor,

which helps cut labor costs and allows human workers to focus on

more complex tasks. Improved Weld Speed and Efficiency: Robots are capable of high-speed welding without sacrificing

quality, which improves production efficiency and throughput.

TECHNICALPARAMETER

Model | OL-RAW1000-3000 | welding power

| 1000W/1500W/2000W/3000W | Electricty demand | 220vac50hz30A / 380vac50hz30A |

welding wavelength

| 1064mm | Cooling system | Air/water | work mode

| Continuous/Modulation | Water chiller brand | Lanqishi.Quanguan,Hanli |

melting depth

| SUS304(0.5-5MM) | Focal length | 200 |

Type of welded joint | Dual Motor Oscillating Welding Head | Power | ≤8kw |

working redius

| 914mm | Repeat positioning accuracy | 0.03mm |

Rated load

| 30kg | operating environment | temperature:5-45℃, Humidity:10%-80% |

Application

Aerospace and Shipbuilding Industry: Degreasing, degreasing and cleaning, paint removal, rust removal. Automobile Manufacturing: Degreasing, cleaning of tire molds, removing coatings from

galvanized sheets before welding. Electronics and Semiconductor Industry: Cleaning of silicon wafers. Marine, Railway, and Bridge Industry: Rust removal, paint removal. Chemical, Food, and Medical Industries: Cleaning small holes in thin metal filter plates. Building Cleaning: General cleaning of buildings. Nuclear Power Plant Reactor Pipe Cleaning: Cleaning of pipes inside nuclear reactor systems.

Factory work shop

Package:

Exhibiton:

Certificate

|