High Frequency Mold Laser Welding Machine Repair Metal Steel Aluminum Alloy Laser

|

|

High Frequency Mold Laser Welding Machine Repair Metal Steel Aluminum Alloy Laser

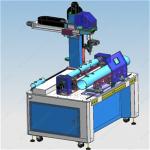

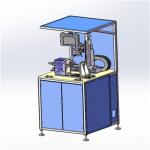

The laser mold welding machine is specially designed for the mold

industry and is used for the repair of precision molds, such as

digital products, mobile phones, toys, automobiles, motorcycles and

other mold manufacturing and molding industries. Through the repair

of the mold, the original mold can be fully utilized again, which

greatly saves the production cost and improves the work efficiency.

This technology can also be applied to modify the design or size of

the mold to shorten the product development cycle.

1. High welding energy, thicker welding wire can be melted compared with general welding machines, and the welding performance is stable;

2. The laser pulse waveform can be adjusted arbitrarily to meet the welding process requirements of complex and special materials;

3. Touch screen interface, simple and intuitive operation.

4. The ceramic concentrating cavity imported from the United Kingdom is used, which is resistant to corrosion and high temperature . The life of the cavity is (9-11) years, and the life of the xenon lamp is more than 8 million times.

5. The world's most advanced automatic shading system is adopted to eliminate the irritation to the eyes during working hours.

6. The laser head can be rotated 360 degrees, the entire optical path can be rotated 360 degrees, and the up and down electric lift, push back and forth, is especially suitable for repairing various large, medium and small molds.

7. The parameter adjustment is controlled by an intelligent remote control, which is simple and fast to operate.

8. The worktable can be raised and lowered electrically and can move in three dimensions

Packing

Certificate

Exhibition

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Steel Mold Laser Welding Machine Aluminum Alloy Mold Laser Welding Machine High Frequency Welding Machine |

|

200W PLC Control Laser Welding Equipment Metal Joining 3D Laser Welding Machine |

|

Automatic Metal Laser Welding Machine 200W For Diverse Materials And Thicknesses |

|

Flexible Fiber Laser Welding Equipment 1064nm Water Cooling Method |

|

Automatic 5kW Laser Welding Machine User Friendly Interface Laser |

|

Degreasing Cleaning Laser Welding Equipment For Aerospace Shipbuilding Industry |

|

Laser welding equipment for aluminum handrail |