In the automotive industry, car tires and rubber seals play vital

roles in ensuring vehicle safety, performance, and comfort. Car

tires endure extreme forces, varying road conditions, and wide -

ranging temperatures during their service life. Rubber seals, on

the other hand, are crucial for maintaining the integrity of

various vehicle components, such as doors, windows, and engine

compartments, by preventing water, dust, and air infiltration. A

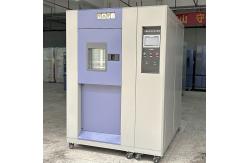

custom thermal cycling test chamber is an essential tool for

manufacturers and researchers in this field. It allows for the

simulation of real - world temperature variations that these rubber

- based components encounter, enabling comprehensive testing to

enhance their quality, durability, and reliability. - Wide Temperature Range: The chamber is designed to achieve a broad temperature spectrum,

typically from - 40°C to 150°C. This wide range enables the

simulation of frigid winter conditions, where tires may experience

reduced flexibility and rubber seals may become brittle, as well as

sweltering summer heat, which can cause tires to soften and rubber

seals to degrade due to excessive heat. The ability to precisely

control temperatures within an accuracy of ±1°C ensures that the

test conditions closely replicate the actual environmental

conditions these components face.

- Flexible Cycling Profiles: Users can create highly customizable thermal cycling profiles.

The heating and cooling rates can be adjusted according to specific

test requirements, usually ranging from 1°C/min to 5°C/min.

Additionally, the hold times at different temperature levels can be

defined. For example, when testing car tires, a slow heating rate

might be set to gradually increase the temperature to simulate the

heat build - up during long - distance driving, followed by a rapid

cooling phase to mimic the sudden drop in temperature when the

vehicle is parked in a shaded area.

- Spatial Adaptability: The chamber's interior is designed to accommodate different sizes

and shapes of car tires and rubber seals. For large - sized car

tires, the chamber can be configured with a spacious interior

volume, with customizable dimensions such as length from 0.4 meters

to 2meters, width from 0.4 meters to 2 meters, and height from 0.5

meters to 2 meters. Smaller rubber seals can be tested in batches,

with specially designed holders and fixtures to ensure they are

evenly exposed to the thermal environment.

- Fixturing and Mounting Solutions: To securely hold the tires and rubber seals during testing, the

chamber is equipped with a variety of customizable fixturing and

mounting systems. For car tires, specialized wheel - like fixtures

can be used to hold the tire in a position similar to its on -

vehicle state, allowing for the application of additional forces

such as rotation or compression during the thermal cycling process.

Rubber seals can be mounted on simulated vehicle components, such

as door frames or engine covers, to accurately replicate their real

- world installation and usage scenarios.

- Multi - Parameter Monitoring: A comprehensive monitoring system is integrated into the chamber.

It continuously monitors temperature, as well as other relevant

parameters such as humidity (if required for specific tests), and

can even be equipped to measure physical properties of the

components under test. For example, strain gauges can be attached

to rubber seals to measure their deformation under different

thermal conditions, while pressure sensors can be used to monitor

the airtightness of a sealed compartment with a rubber seal during

the thermal cycling process.

- Real - Time Data Logging: The chamber is equipped with a data - logging system that records

all monitored parameters in real - time. This data can be stored

for later analysis, allowing manufacturers to identify trends,

detect early signs of component degradation, and optimize the

design and manufacturing processes based on the test results. The

data acquisition frequency is adjustable, typically from [Min Freq]

Hz to [Max Freq] Hz, ensuring that even the most rapid changes in

the test parameters are accurately captured.

| Model | JTS-49-3 | JTS-80-3 | JTS-150-3 | JTS-216-3 | JTS-512-3 | JTS-1000-3 | | Inside dimension(W x D x H) cm | 40 x 35 x 35 | 50 x 40 x 40 | 65x 50 x 50 | 60 x 60 x 60 | 80 x 80 x 80 | 100 x 100 x 100 | | Outside dimension(W x D x H)cm | 128x 190 x 167 | 138 x 196 x 172 | 149 x 192 x 200 | 158 x 220 x 195 | 180 x 240 x 210 | 220 x 240x 220 | | Internal material | #304 Stainless Steel | | External material | Powder coated #304 Stainless Steel | | High temperature range | 60 ℃ ~ 200 ℃ | | Low temperature range | 0 ℃ ~ -70 ℃ | | Test temperature range | 60 ℃ ~ 180 ℃ / 0 ℃ ~ -70 ℃ | | Temperature recovery time | 1-5min | | Temperature stability ℃ | ±2 | | Cylinder switching time | 10s | | High temperature ℃ | 150 | 150 | 150 | 150 | 150 | 150 | | Heating time (min) | |

|