In the medical electronics industry, the reliability and

performance of equipment are of paramount importance. The

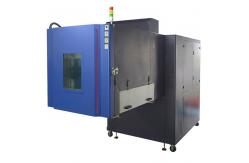

electrodynamic vibration shaker combined with a climatic test

chamber is a specialized and advanced testing solution tailored to

the unique requirements of medical electronic equipment. This

integrated system allows for the simulation of a wide range of

environmental conditions and mechanical stresses that medical

devices may encounter during their lifespan, ensuring their safety,

effectiveness, and durability. This comprehensive test system is designed specifically for medical

electronic equipment, including devices such as patient monitors,

diagnostic imaging equipment, surgical robots, and wearable medical

devices. The primary purpose is to subject these devices to a

combination of mechanical vibrations and climatic factors, such as

temperature, humidity, and altitude variations. By replicating the

real - world conditions that medical electronics may face during

transportation, storage, and normal use, manufacturers can identify

potential weaknesses in the design, improve product quality, and

ensure compliance with strict medical industry standards. - Precise Vibration Control

- The electrodynamic vibration shaker is capable of generating a wide

range of vibration frequencies, typically from 5 Hz to 2000 Hz.

This broad frequency spectrum enables the simulation of different

types of vibrations, from the low - frequency vibrations during

transportation to the high - frequency vibrations caused by

mechanical operations within the medical facility. The vibration

amplitude can be precisely adjusted, with a range of 0.1 mm to 100

mm (peak - to - peak), allowing for the reproduction of various

levels of vibration intensity.

- The shaker can generate vibrations in multiple axes, including

vertical, horizontal, and sometimes even rotational axes. This

multi - axis capability is crucial as medical electronic equipment

may experience complex vibration patterns in different directions

during normal use or transportation. For example, a patient monitor

may be subjected to vibrations in multiple axes when being moved

around a hospital.

- Customizable Vibration Profiles

- Operators have the flexibility to create custom vibration profiles

based on specific test requirements. These profiles can include

continuous vibrations, intermittent shocks, or complex sequences

that mimic the actual vibration scenarios experienced by medical

electronic equipment. For example, a profile can be designed to

simulate the vibrations during a long - distance transportation of

a diagnostic imaging device, including vibrations on different road

surfaces and during air travel.

- High - Quality and Durable Construction

- The electrodynamic vibration shaker is built with high - quality

materials and components to ensure long - term reliability and

performance. The shaker's frame is made of robust steel, providing

a stable and rigid platform for generating vibrations. The

electromagnetic drive system is designed to be efficient and

precise, delivering consistent vibration levels over extended

periods of time.

- Wide Climatic Range

- The climatic test chamber integrated with the vibration shaker can

achieve a broad range of temperature and humidity conditions. The

temperature can typically be adjusted from - 40°C to + 85°C,

allowing for the simulation of extreme cold and hot environments

that medical electronic equipment may encounter during storage or

transportation in different geographical locations. The humidity

control can maintain relative humidity levels from 10% to 95%,

enabling the testing of how devices respond to different moisture

levels.

|