In the fast-paced and highly competitive world of logistics, the

integrity of packaging is a key factor in ensuring the safe and

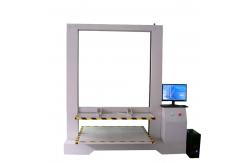

efficient transportation of goods. The Customized Intelligent

Carton Compression Testing Machine for Logistics Companies is a

revolutionary tool designed to meet the specific needs of this

industry. This state-of-the-art testing machine is dedicated to evaluating

the compression strength of cartons used in logistics operations.

Its primary purpose is to determine the maximum load that a carton

can withstand during storage and transportation, thereby helping

logistics companies to prevent damage to goods, reduce losses, and

optimize their supply chain processes. By accurately assessing the

durability of cartons, it enables companies to make informed

decisions about packaging materials, stacking configurations, and

handling procedures. - Robust and Durable Structure

- The testing machine is constructed with a heavy-duty steel frame

that can endure the rigors of continuous use in a logistics

environment. The frame is made from high-strength alloy steel and

is engineered to provide maximum stability and minimal deflection.

The columns and crossbars are precisely machined and assembled to

ensure perfect alignment, which is essential for accurate test

results. The base is designed to absorb vibrations and shocks,

further enhancing the machine's reliability.

- Intelligent Control and Monitoring System

- Equipped with an advanced intelligent control panel, the machine

offers user-friendly operation. It features a touchscreen interface

that allows logistics personnel to easily set test parameters such

as compression speed, maximum load, and test duration. The system

can store and recall multiple test programs, making it convenient

for testing different types of cartons. Real-time monitoring is

provided, displaying the applied load, displacement, and time

elapsed. It also has the ability to automatically detect and record

the peak load and corresponding displacement, eliminating the need

for manual observation and reducing the risk of human error.

- Precision Loading Mechanism

- The loading mechanism consists of a high-precision servo motor and

a ball screw drive. This combination ensures accurate and smooth

application of compressive force. The servo motor allows for

precise control of the loading rate, which can be adjusted from a

slow and steady pace for detailed analysis to a rapid rate to

simulate the dynamic forces experienced during handling and

transportation. The ball screw drive minimizes friction and

backlash, providing consistent and reliable force transmission. The

loading platen is made of hardened steel and is designed to evenly

distribute the load across the carton surface.

- Accurate Sensing and Data Acquisition

- The machine is fitted with high-quality load cells and displacement

sensors. The load cells have a wide measurement range and an

accuracy of within ±0.5% of the full scale, enabling precise

detection of even small changes in load. The displacement sensors

offer a resolution of 0.01 mm, allowing for detailed tracking of

carton deformation. These sensors are connected to a high-speed

data acquisition system that records data at a rate of up to 1000

samples per second. The collected data can be exported in various

formats for further analysis and reporting.

- Versatile Testing Capabilities

- It can accommodate cartons of different sizes and shapes. The

testing platens are adjustable and can be configured to fit

everything from small parcels to large industrial cartons. The

machine is capable of performing both static and dynamic

compression tests. Static tests are useful for determining the

maximum load-bearing capacity of a carton under a steady force,

while dynamic tests can mimic the impacts and vibrations that

cartons may encounter during transit. It can also evaluate the

stacking strength of cartons, which is crucial for optimizing

warehouse storage space and ensuring the stability of palletized

loads.

- Maximum Load Capacity

- Available in models with capacities ranging from 1000 kg to 50,000

kg, the machine can handle cartons of various strengths. For

example, a 1000 kg capacity machine is suitable for testing

lightweight cartons used for small consumer goods, while a 50,000

kg capacity model can assess the robustness of heavy-duty cartons

for industrial machinery or bulk shipments.

- Compression Speed Range

- The compression speed can be set from 0.1 mm/min to 500 mm/min. A

slow speed such as 0.1 mm/min is ideal for conducting detailed

studies of a carton's elastic and plastic deformation behavior. In

contrast, a speed of 500 mm/min can simulate the rapid compression

that might occur during high-speed conveyor belt operations or

rough handling in transit.

- Accuracy of Load Measurement

- With an accuracy of ±0.5% of the full scale, the machine provides

highly reliable load measurements. This level of precision is

essential for logistics companies to ensure that cartons are

properly tested and meet the required strength standards. For

instance, if a carton is supposed to support a certain weight of

goods, the accurate measurement can determine whether it is

suitable for the intended shipment.

- Displacement Measurement Resolution

- The 0.01 mm displacement measurement resolution allows for a

detailed understanding of how the carton deforms under load. This

information can be used to identify potential weak points in the

carton design and to optimize the packaging structure. For example,

it can help determine if a particular corner or seam is more prone

to failure and guide improvements.

- Testing Platform Dimensions

- The adjustable testing platform has a minimum size of 300 mm x 300

mm for testing small samples and can be extended up to 2000 mm x

2000 mm for larger cartons. This flexibility enables the testing of

a wide range of carton sizes commonly used in different logistics

applications.

- Damage Prevention and Loss Reduction

- The primary function of the machine is to conduct accurate

compression tests on cartons to determine their strength. By

identifying cartons that may not be able to withstand the expected

loads during transit, logistics companies can take proactive

measures such as reinforcing the packaging or selecting more

suitable carton materials. This helps to prevent damage to goods,

which in turn reduces losses due to returns, replacements, and

customer dissatisfaction.

- Optimization of Packaging and Stacking

- Through testing different carton designs and materials, logistics

companies can optimize their packaging strategies. They can

determine the most efficient and cost-effective carton types based

on their strength and size. Additionally, the machine's ability to

evaluate stacking strength allows for the development of optimal

pallet configurations. By maximizing the stacking height and weight

without compromising the integrity of the cartons, companies can

save on storage space and transportation costs.

- Compliance with Industry Standards and Regulations

- The testing machine helps logistics companies to ensure that their

packaging complies with relevant industry standards and

regulations. Whether it is meeting the requirements of shipping

carriers or adhering to safety standards for hazardous materials

packaging, accurate test results are crucial. The machine provides

the necessary data to prove that the cartons are fit for purpose

and can withstand the expected handling and transportation

conditions.

- Data-Driven Decision Making

- The detailed data collected by the machine, including

load-displacement curves and peak load values, can be used to make

informed decisions. Logistics companies can analyze this data to

identify trends, compare different suppliers' cartons, and make

improvements to their packaging and handling processes. For

example, if a particular supplier's cartons consistently show lower

strength than expected, the company can work with the supplier to

address the issue or seek alternative sources.

- Stringent Manufacturing Process

- The Customized Intelligent Carton Compression Testing Machine is

manufactured under strict quality control procedures. Each

component, from the steel frame to the sensors and control systems,

is sourced from reliable suppliers and undergoes thorough

inspection and testing. The assembly is carried out by highly

trained technicians in a clean and controlled environment. The

machine is calibrated multiple times during the manufacturing

process using traceable reference standards to ensure its accuracy

and performance.

- Quality Certification and Validation

Our machine has obtained relevant quality certifications and has

been validated by independent testing laboratories. It has been

proven to provide accurate and reliable test results, conforming to

international and national standards for carton compression

testing. We also continuously update and improve our product based

on the latest technological advancements and customer feedback to

ensure its long-term performance and compliance.

- E-commerce Logistics

- An e-commerce logistics company used the testing machine to

evaluate the cartons used for shipping a wide variety of products.

They discovered that some of the cartons used for heavier items had

insufficient compression strength. By switching to a stronger

carton design and adjusting their packaging process, they were able

to reduce the damage rate of goods during transit by 30%, resulting

in significant cost savings and improved customer satisfaction.

- Industrial Goods Logistics

- A logistics provider for industrial machinery tested the cartons

used for shipping large and heavy components. The machine helped

them identify the optimal stacking height and weight limits for

different carton types. By implementing these findings, they were

able to increase the efficiency of their warehouse storage and

transportation operations, reducing the number of trips required

and saving on fuel costs.

- Hazardous Materials Logistics

- A company involved in the transportation of hazardous materials

used the testing machine to ensure that their cartons met the

strict safety and regulatory requirements. The accurate test

results provided the necessary documentation to prove compliance,

allowing them to continue their operations without interruption and

avoid potential fines and legal issues.

- Pre-Sales Technical Consultation

Our team of logistics and packaging experts offers in-depth

technical consultations to help logistics companies understand the

capabilities and suitability of the Customized Intelligent Carton

Compression Testing Machine for their specific operations. We

provide demonstrations and training, tailored to the logistics

industry, to familiarize personnel with the machine's functions and

operation before purchase. We also assist in selecting the

appropriate test methods and accessories based on the types of

cartons and testing requirements. - After-Sales Service and Maintenance

We offer comprehensive after-sales service, including on-site

installation and commissioning. Our technicians are available for

regular maintenance, calibration, and emergency repairs. We provide

spare parts and upgrades to keep the machine operating at peak

performance. We also offer service contracts that include

preventive maintenance and priority technical support, ensuring the

long-term reliability and availability of the testing machine for

logistics companies. - Training and Technical Support

We conduct training programs for new users to ensure they can

effectively operate the Customized Intelligent Carton Compression

Testing Machine and interpret the test results. Our technical

support team is available 24/7 to answer questions, provide

troubleshooting assistance, and offer guidance on test method

optimization and compliance with logistics packaging standards. We

also provide software updates and support for the data acquisition

and analysis systems, enabling logistics companies to take full

advantage of the latest features and technologies in carton

compression testing.

The Customized Intelligent Carton Compression Testing Machine for

Logistics Companies is an essential asset for any organization

looking to enhance the efficiency and reliability of their supply

chain. If you are a logistics company seeking to improve your

packaging quality, optimize your operations, and ensure compliance

with industry standards, this is the ideal solution. Contact us

today to learn more and get a customized quotation. Let us help you

unlock the full potential of your logistics packaging management. |