In the highly demanding and safety-critical aerospace industry, the

performance and reliability of components are non-negotiable. The

Customized Climate Chamber with Vibration is a technological marvel

that offers a comprehensive solution for simulating the extreme and

multifaceted conditions that aerospace parts endure. This specialized chamber is designed to replicate the complex

combination of environmental factors and mechanical stresses that

aerospace components face during their operational lifespan. It

serves aerospace manufacturers, research institutions, and testing

laboratories. The primary goal is to evaluate how components such

as avionics, engines, and structural elements perform and survive

in the presence of simultaneous temperature and humidity

variations, as well as mechanical vibrations. By subjecting these

components to such realistic and harsh testing conditions,

engineers can identify potential weaknesses, optimize designs, and

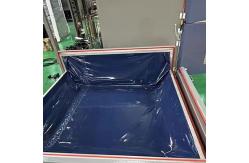

enhance the overall safety and durability of aerospace systems. - Robust and High-Performance Construction

- The chamber is constructed with a heavy-duty, high-strength alloy

framework that can withstand the intense forces generated during

vibration testing and the rigors of extreme temperature and

pressure differentials. The exterior is made from

corrosion-resistant materials, ensuring long-term durability and

protection against the elements. The interior is lined with a

thermally conductive and vibration-damping material to promote

uniform temperature distribution and minimize any interference or

resonance caused by the vibrations. The door is a

precision-engineered component, featuring a multi-point locking

system and a high-quality sealing gasket. This ensures an airtight

and hermetic seal, preventing any leakage of conditioned air and

maintaining the integrity of the simulated environment. A large,

reinforced viewing window, made of tempered and anti-fog glass,

allows for real-time visual inspection of the testing process

without compromising the chamber's environmental or mechanical

integrity.

- Precision Temperature, Humidity, and Vibration Control Systems

- Temperature Control: Capable of maintaining an extensive

temperature range, from -70°C to +150°C, with an outstanding

accuracy of ±0.5°C. This is achieved through a combination of

advanced refrigeration technologies, including cascade

refrigeration for ultra-low temperature capabilities, and

high-power heating elements. The control system incorporates a

sophisticated feedback loop, with multiple temperature sensors

strategically placed throughout the chamber, ensuring uniform

temperature distribution and minimal temperature gradients. The

user-friendly control panel permits the programming of complex

temperature profiles, including rapid temperature ramps, extended

dwell times at specific temperatures, and intricate cycling

sequences, all of which are essential for replicating the dynamic

temperature changes experienced in aerospace applications, such as

during high-altitude flight or re-entry.

- Humidity Control: The humidity control system is equally precise,

with the ability to achieve humidity levels ranging from 5% to 95%

RH (Relative Humidity), with an accuracy of ±3% RH. It employs a

combination of steam injection humidifiers and desiccant

dehumidifiers, integrated with a carefully designed air circulation

system. The chamber is equipped with high-precision humidity

sensors that continuously monitor the internal humidity. The

control system then makes real-time adjustments to the

humidification or dehumidification processes, allowing for the

creation of stable or rapidly changing humidity environments. This

is crucial for testing the effects of moisture on sensitive

electronic components, such as circuit boards and connectors, as

well as the integrity of materials like composites and metals in

humid conditions, which are common in various aerospace scenarios,

from tropical takeoffs to high-altitude condensation.

- Vibration Control: The vibration system is a marvel of engineering,

capable of generating a wide range of frequencies and amplitudes.

It can produce vibrations from a few hertz up to several kilohertz,

with amplitudes adjustable from a fraction of a millimeter to

several centimeters. The vibration table within the chamber is

designed to provide a highly uniform and controlled vibration

field, ensuring that all parts of the tested component experience

the same mechanical stress. The control system allows for the

programming of complex vibration waveforms, including sinusoidal,

random, and shock waveforms, mimicking the diverse vibration

patterns that aerospace components encounter, such as engine

vibrations, turbulence-induced vibrations, and the shock of landing

or takeoff. The vibration system is also equipped with

accelerometers and displacement sensors to accurately measure and

monitor the applied vibrations, ensuring the repeatability and

accuracy of the tests.

- Advanced Instrumentation and Data Acquisition

- The chamber is outfitted with a comprehensive suite of sensors and

instrumentation. In addition to temperature, humidity, and

vibration sensors, it includes pressure sensors to monitor any

changes in air pressure that could impact the test results or the

performance of the samples. Strain gauges can be incorporated to

measure the mechanical strain on components during vibration and

temperature cycling. These sensors are connected to a

state-of-the-art data acquisition system that records and stores

all relevant data. The data acquisition system offers a high

sampling rate, typically ranging from 1000 to 5000 samples per

second, ensuring that even the most rapid changes in environmental

conditions, vibration parameters, or sample performance are

accurately captured. The collected data can be accessed and

analyzed in real-time or retrieved later for in-depth studies. The

system is also compatible with specialized aerospace data analysis

software, enabling the generation of detailed reports and graphical

representations of the test results, which are essential for making

informed engineering decisions.

- Enhanced Safety and Compliance Features

- The Customized Climate Chamber with Vibration for the Aerospace

Industry is designed with multiple layers of safety features. It

incorporates an automatic emergency shutdown system that activates

immediately in the event of any critical malfunction, such as

overheating, overcooling, excessive humidity, or a vibration system

failure. The chamber is equipped with a fire suppression system,

which can quickly extinguish any potential fires that may occur due

to electrical faults or sample failures. The ventilation system is

engineered to remove any harmful gases or fumes that may be

generated during the testing process, protecting both the samples

and the operators. The control panel is designed with safety

interlocks and clear warning indicators to prevent accidental

operation and ensure the well-being of personnel. Additionally, the

chamber complies with all relevant aerospace industry standards and

regulations, such as MIL-STD-810 for environmental testing of

military equipment and RTCA/DO-160 for avionics. This compliance

ensures that the testing procedures are recognized and accepted by

regulatory bodies and industry stakeholders, facilitating the

certification and deployment of aerospace products.

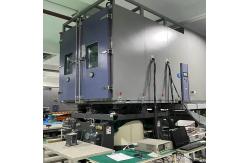

- Chamber Size and Capacity: With a net volume ranging from a few cubic meters to larger sizes

suitable for testing entire aerospace subsystems or small-scale

prototypes, the chamber offers flexibility in accommodating

different component sizes and quantities. The interior dimensions

are carefully designed to ensure proper air circulation, uniform

temperature and humidity distribution, and effective vibration

transmission. For example, a medium-sized chamber might have

interior dimensions of 2 meters x 2 meters x 3 meters, providing

sufficient space for testing a single jet engine component or a

small avionics rack while maintaining the accuracy and integrity of

the simulated environment.

- Temperature Cycling Rate: The chamber can perform temperature cycles at a rate of 2 to 5

cycles per hour, depending on the specific requirements of the test

protocol. For example, it can rapidly cool from +80°C to -50°C in a

matter of minutes and then heat back up, subjecting the samples to

significant thermal stress. The ramp rate can be adjusted,

typically ranging from 1°C per minute to 20°C per minute, allowing

for the simulation of different thermal profiles, such as the rapid

temperature changes experienced during supersonic flight or the

slow temperature gradients in orbital conditions.

- Humidity Cycling Rate: The humidity can be cycled within 15 to 30 minutes, allowing for

the simulation of rapid changes in moisture conditions. This

replicates the transitions that may occur, for example, when an

aircraft moves from a dry, high-altitude environment to a humid,

low-altitude landing zone or vice versa. The chamber can quickly

adjust the humidity level from a low value, such as 10% RH, to a

high value, such as 90% RH, and back, enabling the evaluation of

the component's response to such changes, especially in terms of

corrosion, electrical conductivity, and material integrity.

- Vibration Frequency and Amplitude Range: The vibration system can generate frequencies from 5 Hz to 5000

Hz, covering the typical frequency range of aerospace vibrations.

The amplitude can be adjusted from 0.1 mm to 50 mm, depending on

the specific test requirements. For example, during engine

vibration testing, frequencies in the range of 100 Hz to 1000 Hz

with amplitudes of a few millimeters might be applied, while for

shock testing related to landing or takeoff, higher amplitudes and

shorter-duration shock pulses at lower frequencies, such as 5 Hz to

50 Hz with amplitudes up to 50 mm, could be used.

- Data Acquisition Rate: The data acquisition system samples sensor data at a rate of 3000

samples per second, ensuring that even the slightest and most rapid

changes in temperature, humidity, pressure, vibration, or strain

during the test are accurately recorded. This high sampling rate

provides engineers and scientists with detailed and accurate

information about the performance and behavior of the tested

samples, enabling them to identify potential issues and make

informed design improvements.

- Compliance with Industry Standards: The chamber is fully compliant with MIL-STD-810, which covers a

wide range of environmental conditions and test methods relevant to

military and aerospace equipment, and RTCA/DO-160, which focuses

specifically on the environmental testing of avionics. This

compliance ensures that the testing is conducted in accordance with

the strict requirements and procedures established by the aerospace

industry, providing confidence in the reliability and performance

of the tested products.

- Accurate Simulation of Aerospace Operational Environments

- The primary function of this chamber is to provide a highly

accurate and realistic simulation of the temperature, humidity, and

vibration conditions that aerospace components will face during

their operational lifespan. By precisely controlling these

parameters, it allows for the evaluation of how components and

systems will perform and degrade over time. For example, it can

determine if an avionics system will experience malfunctions due to

overheating and vibration-induced stress in a hot and turbulent

flight environment or if a satellite component will withstand the

extreme temperature and vibration conditions during launch and

orbital operations. This information is invaluable for aerospace

engineers to optimize their designs, select appropriate materials,

and improve the overall reliability and durability of their

products.

- The ability to conduct repeatable tests with different temperature,

humidity, and vibration profiles, as mandated by industry

standards, is also a crucial function. This helps in comparing the

performance of various product designs or manufacturing processes

and identifying the most suitable solution. For instance, a defense

contractor can test multiple prototypes of a new missile guidance

system under the same set of temperature, humidity, and vibration

cycling conditions and analyze the results to select the most

reliable and accurate design.

- Enhanced Aerospace Product Quality and Mission Success Assurance

- Through comprehensive testing in the Customized Climate Chamber

with Vibration, aerospace product developers can identify and

address potential issues in their designs. If a component shows

signs of failure or degradation during the test, appropriate

measures can be taken, such as modifying the material composition,

improving the manufacturing process, or adding additional vibration

damping or thermal protection features. This leads to the

development of more reliable and durable aerospace products,

reducing the risk of mission failures and enhancing the safety of

personnel. In the research and development field, it allows for the

exploration of new materials and technologies, providing valuable

data on their behavior under extreme temperature, humidity, and

vibration conditions. For example, researchers can study the

performance of new composite materials for aircraft structures or

advanced vibration isolation systems for sensitive avionics.

- The chamber also serves as a powerful tool for quality control. By

subjecting products to standardized environmental and vibration

tests, manufacturers can ensure that their products meet the

required quality and performance standards. This helps in building

a reputation for quality and reliability in the highly competitive

aerospace market, which is essential for winning contracts and

maintaining the trust of customers.

- Compliance with Aerospace Industry Standards and Regulations

- The compliance of the test chamber with relevant aerospace industry

standards is a key aspect of its functionality. The aerospace

industry is highly regulated, and products must meet specific

standards to be accepted for use. By using this chamber to conduct

tests in accordance with standards like MIL-STD-810 and

RTCA/DO-160, manufacturers can prove that their products are safe

and reliable. Regulatory bodies and military customers rely on

accurate test results obtained from such chambers to enforce safety

and quality regulations, ensuring the proper functioning of

aerospace equipment and the success of missions.

- Stringent Manufacturing Process

- The Customized Climate Chamber with Vibration for the Aerospace

Industry is manufactured under strict quality control procedures.

Each component, from the refrigeration system to the vibration

table and sensors, is carefully sourced and inspected for quality

and performance. The assembly process is carried out by highly

trained technicians with extensive experience in aerospace testing

equipment manufacturing in a clean and controlled environment. The

chamber undergoes a series of calibration and validation tests

during the manufacturing process to ensure that it meets the

required accuracy and performance standards.

- The calibration of the temperature, humidity, vibration, and other

sensors is a critical and regular part of the manufacturing

process. It is performed using traceable reference standards that

are calibrated to the highest levels of accuracy, guaranteeing the

reproducibility of the test results. Rigorous quality audits and

inspections are conducted at various stages of production to

maintain the highest level of product quality and compliance with

aerospace standards.

- Quality Certification and Validation

Our chamber has obtained relevant quality certifications and has

been validated by independent aerospace testing laboratories. It

has been proven to provide accurate and reliable test results,

conforming to the relevant industry standards. We also continuously

update and improve our product based on the latest technological

advancements and customer feedback from the aerospace industry to

ensure its long-term performance and compliance.

- Aerospace Component Testing

- A major aerospace manufacturer used the Customized Climate Chamber

with Vibration to test a new jet engine turbine blade. The tests

revealed that the blade was prone to cracking under the combined

stress of high temperature and vibration. By redesigning the

blade's cooling channels and using a more heat-resistant alloy,

they were able to improve its durability and performance, reducing

the risk of engine failure and increasing the efficiency of the jet

engine.

- An aerospace electronics company tested their new avionics system

in the chamber. The testing identified a weakness in the solder

joints of the circuit boards, which could lead to intermittent

electrical failures in a vibrating and temperature-changing

environment. By improving the soldering process and adding

vibration-damping components to the circuit board assembly, they

were able to enhance the reliability of the avionics system,

ensuring the safety and proper functioning of the aircraft's

navigation and communication systems.

- Research and Development in Aerospace Materials

- A research institution focused on aerospace materials used the

chamber to study the effects of temperature, humidity, and

vibration on the performance of new carbon fiber composites. The

data obtained led to the development of improved manufacturing

processes and fiber-matrix interfaces, increasing the strength and

durability of the composites in extreme aerospace conditions.

- Another research institution investigated the impact of

environmental and mechanical stress on the performance of shape

memory alloys for aerospace applications. The results of their

studies enabled the development of more efficient and reliable

shape memory alloy actuators, which could be used in various

aerospace systems, such as adaptive wing structures and smart

landing gear.

- Space Exploration and Satellite Technology

- A space agency used the Customized Climate Chamber with Vibration

to test satellite components before launch. The testing helped them

identify and address potential issues with the components' ability

to withstand the extreme temperature and vibration conditions

during launch and in space. By making improvements and conducting

further tests, they were able to increase the reliability and

lifespan of the satellites, ensuring the success of their space

missions.

- A satellite manufacturing company tested their new solar panel

technology in the chamber. The tests showed that the panels were

sensitive to vibration-induced damage and temperature fluctuations.

By adding vibration isolation and thermal management features to

the panel design, they were able to improve their performance and

durability in the harsh space environment.

- Pre-Sales Technical Consultation

Our team of aerospace experts provides in-depth technical

consultations to help customers understand the capabilities and

suitability of the Customized Climate Chamber with Vibration for

their specific testing needs. We offer demonstrations and training,

tailored to the aerospace industry, to familiarize customers with

the operation and functionality of the equipment before purchase.

We also assist in selecting the appropriate test methods and

accessories based on the products to be tested. - After-Sales Service and Maintenance

We offer comprehensive after-sales service, including on-site

installation and commissioning. Our technicians are available for

regular maintenance, calibration, and emergency repairs. We provide

spare parts and upgrades to keep the test chamber operating at peak

performance. We also offer service contracts that include

preventive maintenance and priority technical support, ensuring the

long-term reliability and availability of the equipment for

aerospace testing. - Training and Technical Support

We conduct training programs for new users to ensure they can

effectively operate the Customized Climate Chamber with Vibration

and interpret the test results. Our technical support team is

available 24/7 to answer questions, provide troubleshooting

assistance, and offer guidance on test method optimization and

compliance with aerospace industry standards. We also provide

software updates and support for the data acquisition and analysis

systems, enabling customers to take full advantage of the latest

features and technologies in aerospace environmental and vibration

testing.

The Customized Climate Chamber with Vibration for the Aerospace

Industry is an essential asset for any organization involved in the

development, manufacturing, or testing of aerospace products. If

you are looking to enhance your testing capabilities, ensure

compliance with industry standards, or drive innovation in the

aerospace field, this is the ideal solution. Contact us today to

learn more and get a customized quotation. Let us help you unlock

the full potential of your aerospace product quality control and

environmental and vibration testing |