In the world of manufacturing, the reliability and longevity of

plastic parts are non-negotiable. The HALT HASS & AGREE

Vibration Test Chambers, purpose-built for the NES M0132 Thermal

Cycle Test of “NTC-1-5A” plastic parts, stand as a paragon of

precision and innovation in ensuring the highest quality of these

components. This advanced vibration test chamber is dedicated to subjecting

“NTC-1-5A” plastic parts to the comprehensive NES M0132 thermal

cycle testing regimen. It serves a diverse clientele, including

automotive, aerospace, electronics, and consumer goods

manufacturers. The core objective is to meticulously evaluate the

ability of these plastic parts to endure the rigors of repeated and

extreme temperature changes, combined with the added stress of

vibration. By faithfully replicating the real-world and accelerated

conditions that plastic parts may face during their operational

lifespan, manufacturers can identify and rectify potential

weaknesses, optimize material formulations and manufacturing

processes, and ultimately enhance the overall durability and

performance of their products. - Tailored Chamber Design for Plastic Part Testing

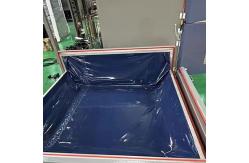

- The chamber is constructed with dimensions and an interior layout

that are optimized to house the specific “NTC-1-5A” plastic parts.

The walls are fabricated from high-strength, thermally stable

materials that provide excellent insulation and durability. The

door is engineered with a precision sealing mechanism and a large

viewing window, allowing operators to closely monitor the testing

process without perturbing the internal environment. The interior

is equipped with adjustable racks and fixtures, ensuring proper

positioning and uniform exposure of the plastic parts to both

thermal cycling and vibration.

- Precision Temperature and Vibration Control Systems

- Temperature Cycling Capability: The chamber can achieve a wide

temperature range, typically from -40°C to +120°C, with an accuracy

of ±0.3°C. It is furnished with a high-performance refrigeration

unit and powerful heating elements, coordinated by a sophisticated

control algorithm and multiple temperature sensors. This enables

the chamber to execute precise and rapid temperature cycling,

replicating the harsh thermal environments that plastic parts may

experience, such as in extreme weather conditions or near heat

sources.

- Vibration System: The chamber is outfitted with a high-precision

vibration platform that can generate a wide spectrum of vibration

frequencies and amplitudes. It can produce vibrations from 5 Hz to

2000 Hz with amplitudes up to 50 mm. The vibration system is

designed to mimic various real-world vibration sources, including

machinery vibrations, transportation-induced jolts, and the dynamic

forces associated with product usage. The vibration control system

offers remarkable accuracy, allowing for the programming of complex

vibration profiles and real-time adjustments.

- Intuitive Control Panel and Data Acquisition Interface

- The control panel is crafted for user-friendliness, affording

operators effortless access to all test parameters. They can

readily set and adjust temperature limits, cycling times, vibration

frequencies, amplitudes, and test durations. The panel also

presents real-time information regarding the current temperature,

vibration status, and any alarms or warnings. The chamber is

integrated with a comprehensive data acquisition system that

records all pertinent test data. This encompasses temperature

histories, vibration waveforms, and any observable changes in the

physical or mechanical properties of the plastic parts. The data

can be stored in a built-in memory or exported to external storage

devices for in-depth analysis. The system is also capable of

generating detailed test reports in various formats.

- Safety Features and Alarms

- To safeguard operators and the integrity of the testing process, a

suite of safety features is incorporated. These include

over-temperature and over-vibration protection systems, emergency

stop buttons, and alarms for abnormal temperature fluctuations,

vibration malfunctions, or any other equipment failures. The

chamber is also equipped with proper ventilation and exhaust

systems to handle any potentially harmful gases or vapors that may

be emitted from the plastic parts during thermal cycling and

vibration testing.

- Temperature Range and Accuracy

- The -40°C to +120°C temperature range with ±0.3°C accuracy offers a

comprehensive and precise testing environment. This wide range

allows for the evaluation of plastic parts' performance under both

extremely cold and hot conditions. Different plastic materials have

varying glass transition temperatures and thermal expansion

coefficients, and this accurate temperature control ensures that

the test conditions are precisely maintained, providing reliable

and repeatable results.

- Vibration Parameters

- The vibration system's ability to produce frequencies from 5 Hz to

2000 Hz and amplitudes up to 50 mm provides a thorough assessment

of the plastic parts. Low-frequency vibrations can mimic the slow

oscillations of a product during storage or transportation, while

high-frequency vibr

|