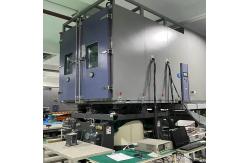

In the packaging industry, the performance and durability of

corrugated containers are of utmost importance. To ensure that

these containers can withstand the rigors of transportation and

storage, accurate and comprehensive testing is essential. The

customized environmental chamber with a vibration table is a

cutting-edge solution designed specifically for laboratory testing

of corrugated containers. This advanced testing apparatus is dedicated to simulating the

various environmental and mechanical stresses that corrugated

containers may experience during their lifecycle. It serves the

packaging manufacturing industry, shipping companies, and quality

control laboratories. The primary objective is to evaluate the

integrity and strength of corrugated containers under different

temperature, humidity, and vibration conditions. By conducting

these tests, manufacturers can optimize their container designs,

select appropriate materials, and ensure compliance with industry

standards and regulations. - Robust and Insulated Chamber Construction

- The environmental chamber is built with a heavy-duty steel frame

that provides exceptional rigidity and stability. The frame is

coated with a corrosion-resistant finish to enhance its durability.

The chamber walls are made of high-quality insulation materials,

which minimize heat transfer and maintain precise temperature and

humidity levels. The insulation is carefully engineered to

withstand the rigors of continuous testing and prevent any external

factors from interfering with the internal test environment. The

chamber is also equipped with a hermetic door seal, ensuring a

leak-free enclosure and consistent test conditions.

- Precision Temperature and Humidity Control System

- The chamber features a highly accurate temperature and humidity

control system. It can maintain a wide temperature range, from

-20°C to +80°C, with an accuracy of ±0.5°C. The humidity control

range extends from 10% to 95% relative humidity, with an accuracy

of ±3% RH. The system utilizes advanced refrigeration units,

electric heaters, humidifiers, and dehumidifiers to achieve and

maintain the desired environmental conditions. Temperature and

humidity sensors are strategically placed within the chamber to

provide real-time feedback, enabling the control system to make

rapid and precise adjustments.

- High-Performance Vibration Table

- The vibration table incorporated into the system is engineered for

precision and power. It can generate a wide range of vibration

frequencies, typically from 5 Hz to 2000 Hz, covering the spectrum

of vibrations encountered during transportation. The amplitude of

vibration can be precisely controlled, ranging from a few

micrometers to several centimeters. The table is equipped with a

high-torque motor and advanced servo control system, ensuring

accurate and repeatable vibration patterns. It also features a

rigid surface and excellent dynamic balance, minimizing any

unwanted resonances or vibrations that could affect the test

results.

- Synchronized Control and Data Acquisition

- The system is equipped with a sophisticated control panel that

allows for seamless synchronization of vibration and environmental

parameters. Operators can precisely program the sequence and

intensity of vibrations, temperature changes, and humidity levels,

creating custom test profiles. The control panel also provides

real-time monitoring of all test parameters, including temperature,

humidity, vibration frequency, amplitude, and container status. The

data acquisition system records detailed information about the

test, such as temperature and humidity profiles, vibration

waveforms, and any changes in the physical properties of the

corrugated container. The acquired data can be stored in a variety

of formats and analyzed using specialized software to generate

comprehensive test reports.

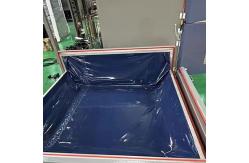

- Customizable Interior and Fixtures

- The chamber offers a customizable interior space to accommodate

different sizes and shapes of corrugated containers. It can be

equipped with adjustable racks, shelves, and mounting fixtures,

allowing for flexible test setups. The interior surfaces are made

of non-corrosive and non-reactive materials to prevent any

contamination or interaction with the containers. Additionally, the

chamber can be fitted with various accessories, such as cable ports

for sensor connections, viewing windows for visual inspection, and

access doors for easy container loading and unloading.

- Maximum Vibration Displacement

- The vibration table can achieve a maximum displacement of ±50 mm.

This significant displacement capacity allows for the simulation of

severe vibration conditions, such as those experienced during rough

transportation on bumpy roads or in vibrating trucks. For example,

in testing the durability of corrugated containers used for

shipping heavy machinery parts, a large vibration displacement can

help uncover potential weaknesses in the container design or

material under extreme mechanical stress.

- Vibration Frequency Range

- As mentioned, the frequency range of 5 Hz to 2000 Hz covers a wide

spectrum of vibrations. Low-frequency vibrations can affect the

stability and alignment of larger containers, while high-frequency

vibrations can cause fatigue and failure in the corrugated board

and its joints. Testing across this frequency range ensures a

comprehensive evaluation of a container's performance under

different vibration scenarios.

- Thermal Shock Temperature Range

- The ability to transition from -20°C to +80°C provides a broad

range of thermal shock conditions. This is crucial for assessing

how corrugated containers respond to sudden temperature changes,

such as when moving from a cold storage facility to a hot

transportation vehicle or vice versa. In the food and

pharmaceutical industries, where products may be stored and shipped

under different temperature conditions, this testing helps ensure

the integrity of the packaging and the safety of the contents.

- Temperature Transition Rate

- The chamber can achieve a temperature transition rate of up to 3°C

per minute. This rapid rate of temperature change is essential for

accurately simulating real-world thermal shock events. For

instance, in testing the integrity of a corrugated container used

for shipping electronic components, a fast temperature transition

can reveal any cracks or weaknesses that may develop due to thermal

stress.

- Maximum Payload Capacity

|