In the world of product testing and quality assurance, the need to

accurately simulate real-world environmental conditions has led to

the development of advanced testing equipment. The single axis

rotating table combined with a climatic chamber is a remarkable

innovation that offers a comprehensive solution for evaluating the

performance and durability of various products under complex and

dynamic environmental stressors. This integrated testing apparatus is designed to subject samples to

a combination of rotational motion and controlled climatic

conditions. It caters to a wide range of industries, including

aerospace, automotive, defense, and electronics. The primary

purpose is to assess how products behave when exposed to

simultaneous changes in temperature, humidity, and orientation. By

replicating the multi-faceted challenges that products may

encounter during their operational lifetimes, manufacturers and

researchers can identify potential weaknesses, optimize designs,

and ensure compliance with stringent industry standards. - Robust and Modular Design

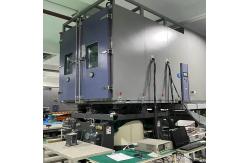

- The single axis rotating table and climatic chamber are constructed

with a heavy-duty steel frame that provides exceptional stability

and durability. The frame is engineered in a modular fashion,

allowing for easy customization and integration of different

components. The rotating table is mounted within the chamber in a

way that ensures seamless operation and minimal interference with

the climatic control systems. The modular design also facilitates

future upgrades and modifications, enabling the equipment to adapt

to evolving testing requirements.

- Precision Climatic Control System

- The climatic chamber features a highly accurate temperature and

humidity control system. It can maintain a wide temperature range,

from -40°C to +150°C, with an accuracy of ±0.5°C. The humidity

control range extends from 10% to 98% relative humidity, with an

accuracy of ±2% RH. The system utilizes advanced refrigeration

units, electric heaters, humidifiers, and dehumidifiers to achieve

and maintain the desired environmental conditions. Temperature and

humidity sensors are strategically placed within the chamber to

provide real-time feedback, allowing the control system to make

rapid and precise adjustments.

- High-Performance Rotating Table

- The single axis rotating table is engineered for precision and

reliability. It can achieve a wide range of rotational speeds,

typically from 0.1 to 100 revolutions per minute (RPM). The table

is equipped with a high-torque motor and advanced servo control

system, ensuring accurate and repeatable rotational motion. It also

features a rigid surface and excellent dynamic balance, minimizing

any unwanted vibrations or wobbles that could affect the test

results. The table can support a significant payload, with a

maximum capacity of up to 1000 kg, allowing for the testing of a

wide variety of products.

- Synchronized Control and Data Acquisition

- The system is equipped with a sophisticated control panel that

enables seamless synchronization of the rotating table and climatic

parameters. Operators can precisely program the sequence and

intensity of rotations, temperature changes, and humidity levels,

creating custom test profiles. The control panel also provides

real-time monitoring of all test parameters, including temperature,

humidity, rotational speed, and sample status. The data acquisition

system records detailed information about the test, such as

temperature and humidity profiles, rotational motion data, and any

changes in the physical properties of the sample. The acquired data

can be stored in a variety of formats and analyzed using

specialized software to generate comprehensive test reports.

- Safety and Protection Mechanisms

- To ensure the safety of operators and the integrity of the testing

process, the system is equipped with a range of safety features. It

has emergency stop buttons strategically located for immediate

shutdown in case of any abnormal situation. The rotating table and

climatic chamber are enclosed in a protective housing made of

durable and heat-resistant materials. The housing is designed to

contain any potential flying debris or leaks from the chamber.

Additionally, the system has built-in safety interlocks that

prevent unauthorized access or operation when the equipment is in

use.

- Maximum Rotational Speed and Acceleration

- The rotating table can reach a maximum rotational speed of 100 RPM

and an acceleration of up to 5 m/s². These parameters allow for the

simulation of a wide range of real-world rotational scenarios, from

slow and steady movements to rapid and dynamic rotations. For

example, in aerospace applications, components may experience

different rotational speeds and accelerations during flight

maneuvers, and this equipment can accurately replicate those

conditions.

- Temperature Cycling Range and Rate

- The temperature within the chamber can be cycled from -40°C to

+150°C, with a maximum rate of change of 5°C per minute. This wide

temperature range and rapid cycling rate are essential for testing

the thermal resistance and durability of products. In the

automotive industry, for instance, engine components need to

withstand significant temperature fluctuations, and this chamber

can simulate those conditions to evaluate the performance of the

parts.

- Humidity Cycling Range and Rate

- The humidity can be cycled from 10% to 98% relative humidity, with

a rate of change of up to 10% RH per minute. This enables the

assessment of a product's resistance to moisture absorption,

condensation, and drying. In the electronics industry, high

humidity can cause corrosion and short circuits, and this testing

equipment can help identify potential issues related to humidity.

- Testing Volume and Payload Capacity

- The chamber offers a customizable testing volume, with options

ranging from 1 m³ to 20 m³. The payload capacity of the rotating

table is up to 1000 kg. This flexibility allows for the testing of

a wide variety of products, from small electronic modules to large

mechanical assemblies. For example, in the defense industry, it can

be used to test the performance of weapon systems or large

communication equipment under different environmental and

rotational conditions.

- Rotation Axis Stability and Precision

- The single axis of rotation is highly stable and precise, with a

positional accuracy of ±0.1°. This level of precision ensures that

the orientation of the sample during testing is accurately

controlled, which is crucial for obtaining reliable and repeatable

test results. In applications where the alignment of components is

critical, such as in optical or precision engineering, this feature

is of utmost importance.

|