In the ever-evolving landscape of modern industries, the need for

comprehensive and accurate product testing has reached new heights.

The Customization Temperature Humidity Vibration Chamber Three

Integrated Test Chamber AGREE Test Chamber stands as a paragon of

technological prowess, catering to the stringent demands of sectors

such as aerospace, defense, electronics, and automotive. This highly sophisticated chamber combines temperature, humidity,

and vibration testing capabilities in a single, customizable unit.

Inspired by the military standard "Advisory Group on Reliability of

Electronic Equipment" (AGREE), it is designed to subject products

and components to a gamut of environmental stressors. The primary

objective is to meticulously evaluate how items will perform and

endure under the most complex and extreme conditions they might

encounter during their operational lifespan. By replicating a vast

array of temperature gradients, humidity levels, and vibration

frequencies, it empowers manufacturers and researchers to unearth

potential weaknesses, refine designs, and ensure seamless

compliance with industry-specific norms and regulations. - Robust and Modular Construction

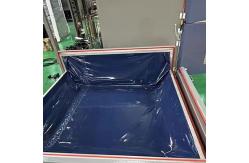

- The chamber is crafted with a heavy-duty framework, typically

fabricated from high-strength alloy steel, to withstand the rigors

of concurrent temperature, humidity, and vibration testing. The

interior is lined with a non-reactive and seamless material like

stainless steel or a specialized high-temperature polymer,

precluding any interaction between the chamber environment and the

test specimens. Premium insulation is integrated to curtail heat

and moisture transfer, thereby guaranteeing precise temperature and

humidity control. The vibration system is ingeniously incorporated,

featuring a highly adjustable vibration platform that can

accommodate diverse sample sizes and weights. The door is

engineered to provide an airtight seal, equipped with a reliable

locking mechanism and a heavy-duty gasket. A generously sized

viewing window, made of tempered glass with anti-fog and

anti-scratch coatings, permits continuous visual surveillance of

the testing process without perturbing the internal environment.

- Precision Control Systems

- Temperature Control: The temperature control system is

ultra-precise, capable of maintaining a wide temperature spectrum,

ranging from -80°C to +180°C, with an accuracy of ±0.2°C. It

deploys advanced refrigeration and heating technologies, in tandem

with a highly sophisticated feedback loop and multiple

strategically positioned temperature sensors. This ensures uniform

temperature distribution throughout the chamber and rapid

temperature modulation, essential for efficient testing. The system

also incorporates fail-safe features to avert overheating or

overcooling, safeguarding both the samples and the chamber

infrastructure.

- Humidity Control: The humidity control system is equally exacting,

with the capacity to adjust the relative humidity from 2% to 98%

RH, maintaining an accuracy of ±1.5% RH. The chamber is outfitted

with a high-efficiency humidifier and dehumidifier that work in

harmony to effectuate rapid and accurate humidity adjustments.

Stringent measures are taken to prevent condensation, which could

compromise test results and damage the samples. The system also

encompasses a dew point control function, vital for sustaining the

correct moisture equilibrium within the chamber.

- Vibration Control: The vibration control system is engineered to

generate an extensive range of vibration frequencies and

amplitudes. It can simulate a plethora of vibration profiles, from

simple harmonic oscillations to highly complex random vibrations

that mirror real-world scenarios such as those experienced during

seismic events, transportation, or heavy machinery operation. The

system is highly programmable, enabling users to concoct and store

bespoke vibration sequences. It also features built-in safety

protocols to preclude excessive vibrations that could harm the

samples or the chamber. The control panel for the vibration system

is user-friendly and intuitive, streamlining the setup and

adjustment of vibration parameters.

- Programmability: The overarching control panel of the chamber is

highly programmable, endowing users with the ability to design and

store intricate test profiles that amalgamate temperature,

humidity, and vibration settings. This permits the simulation of a

vast panoply of environmental and operational conditions. For

example, it can replicate the extreme conditions a military-grade

electronics component might face during a battlefield deployment,

including rapid temperature shifts, high humidity, and intense

vibrations. The control panel displays real-time information about

all parameters, including temperature, humidity, vibration

frequency, amplitude, and the progress of the test program.

- Advanced Instrumentation and Data Acquisition

- The chamber is equipped with a comprehensive suite of sensors.

Temperature sensors are evenly dispersed to detect any temperature

differentials and ensure a homogeneous thermal milieu. Humidity

sensors furnish real-time data on relative humidity levels.

Vibration sensors measure the amplitude, frequency, and

acceleration of the vibrations. These sensors are interfaced with a

state-of-the-art data acquisition system that records and archives

all the measured data. The data can be accessed and analyzed in

real-time or retrieved subsequently for in-depth studies. The data

acquisition system is highly flexible and can be integrated with

external software and databases, facilitating seamless data

transfer and analysis. It can also be configured to dispatch

notifications and reports automatically, conserving time and effort

for the users. Additionally, the control panel includes built-in

alarms and safety features that alert users in case of any abnormal

conditions, such as temperature or humidity excursions beyond the

set limits, power failures, or equipment malfunctions.

- Volume and Dimensions: The chamber is available in a variety of sizes to meet diverse

testing requisites. The volume can span from a few cubic feet for

testing diminutive components to capacious chambers with several

cubic meters of space for accommodating voluminous products or

multiple samples. The interior dimensions are meticulously

optimized to ensure efficient dissemination of temperature,

humidity, and vibration, ensuring that all parts of the tested

samples are subjected to consistent environmental and mechanical

stress. The external dimensions are configured to fit within a

standard laboratory or production facility, taking into account

factors such as access, ventilation, and clearance.

- Temperature Uniformity: The temperature uniformity within the chamber is maintained

within ±0.3°C. This ensures that all parts of the tested samples

are exposed to an almost identical thermal environment, which is

pivotal for obtaining accurate and reliable test results.

- Humidity Uniformity: The humidity uniformity is within ±2% RH. This level of

consistency in humidity distribution allows for highly precise

testing of samples that are sensitive to moisture levels.

- Vibration Uniformity: The vibration system is designed to provide uniform vibration

across the testing platform. The variation in vibration amplitude

and frequency is held within a minuscule tolerance, typically ±3%,

ensuring that all parts of the sample are subjected to the same

mechanical stress.

- Stability: Both the temperature and humidity stability are exemplary, with

negligible fluctuations over time. The vibration system also

exhibits high stability, maintaining the set vibration parameters

with unerring accuracy throughout the test. This allows for

long-term testing and the evaluation of a sample's performance

under stable environmental and mechanical conditions, as well as

its ability to withstand changes over extended periods.

- Accurate Simulation of Harsh and Complex Environments

- The cardinal function of this chamber is to furnish a highly

accurate and realistic simulation of specific temperature,

humidity, and vibration conditions. By precisely manipulating these

parameters, it enables users to appraise how products and samples

will behave in a multitude of real-world situations. For instance,

in the aerospace industry, it can test the performance of

flight-critical components under the extreme temperature and

humidity variations that occur at stratospheric altitudes, combined

with the vibrations induced by engine operation and air turbulence.

In the electronics industry, it can assess the durability of

circuit boards and microchips under the combined stress of

temperature cycling, humidity, and vibrations from nearby machinery

or during transportation.

- The capacity to create elaborate test profiles that integrate

diverse environmental and vibration conditions is also a valuable

asset. This can assist in uncovering latent weaknesses or failure

points in products that might elude detection under

single-parameter testing. For example, a product that functions

optimally under static temperature and humidity conditions may

falter when subjected to concurrent vibrations and rapid

temperature transitions. The chamber can faithfully replicate such

scenarios to ascertain the product's true durability and

performance boundaries.

- Enhanced Product Quality and Research Efficacy

- Through exhaustive testing in the chamber, manufacturers can

identify and rectify potential issues in their products. If a

product exhibits signs of degradation or failure under specific

temperature, humidity, and vibration conditions, appropriate

remedial measures can be instituted, such as redesigning the

product, altering the material composition, or refining the

manufacturing process. This culminates in the development of more

stable and reliable products, reducing the likelihood of failures

and recalls. In the research domain, it permits the exploration of

novel materials and the comprehension of their properties under

combined environmental and mechanical duress, which can precipitate

significant scientific breakthroughs.

- The test chamber also serves as an invaluable tool for quality

control. By subjecting products to standardized tests that mimic

real-world conditions, manufacturers can ensure that their products

meet the requisite quality and performance benchmarks. This

bolsters customer confidence and sustains a favorable reputation in

the market.

- Stringent Compliance with Industry Standards and Regulations

- Numerous industries are governed by exacting standards and

regulations regarding product testing under specific temperature,

humidity, and vibration conditions. The Customization Temperature

Humidity Vibration Chamber Three Integrated Test Chamber AGREE Test

Chamber is a dependable instrument for ensuring compliance. For

example, in the aerospace and defense sectors, components must

adhere to stringent standards for reliability and durability. In

the electronics industry, products need to withstand a gamut of

environmental and mechanical stresses to ensure proper operation.

By employing this chamber to conduct tests in accordance with

relevant standards, manufacturers can validate that their products

meet the necessary criteria, facilitating market access and

augmenting consumer trust. Regulatory bodies rely on accurate test

results obtained from such chambers to enforce safety and quality

regulations.

- Stringent Manufacturing Process

- The Customization Temperature Humidity Vibration Chamber Three

Integrated Test Chamber AGREE Test Chamber is manufactured under a

regimen of strict quality control procedures. Each component, from

the insulation panels to the environmental and vibration control

systems, is painstakingly sourced and inspected for quality and

performance. The assembly process is executed by highly trained

technicians in a sterile and controlled environment, ensuring the

proper installation and functionality of all parts.

- The calibration of the temperature, humidity, vibration, and other

sensors and control systems is a critical and recurrent aspect of

the manufacturing process. It is carried out using traceable

reference standards to vouchsafe the accuracy and reproducibility

of the test results. Rigorous quality audits and inspections are

conducted at various stages of production to uphold the highest

level of product quality.

- Quality Certification and Validation

Our chamber has obtained relevant quality certifications and has

been validated by independent testing laboratories. It has been

proven to provide accurate and reliable test results, conforming to

the germane international and national standards. We also

perpetually update and enhance our product based on the latest

technological advancements and customer feedback to ensure its

long-term performance and compliance.

|