In the dynamic and innovation-driven electronics industry, the

reliability and durability of electronic components are

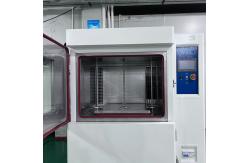

non-negotiable. Customized Thermal Shock Test Chambers for the

Electronics Industry have emerged as a crucial tool for

manufacturers and researchers alike, enabling them to subject

electronic parts to extreme temperature variations and assess their

performance under the harshest thermal stress conditions. These specialized chambers are designed to create rapid and extreme

temperature transitions, precisely simulating the thermal shocks

that electronic components may encounter during their lifecycle.

From the moment a smartphone is taken from a cold winter day into a

warm indoor environment, to the temperature fluctuations

experienced by satellite electronics in the harsh vacuum of space,

these chambers replicate such scenarios. The primary purpose is to

identify any weaknesses or potential failures in electronic

components, circuit boards, connectors, and other parts, ensuring

that they can withstand the rigors of real-world use and maintain

optimal functionality. - Robust and Insulated Chamber Structure

- The chamber is constructed with high-quality, heat-resistant

materials to endure the continuous and intense thermal cycling. The

exterior is typically made of heavy-duty steel, providing excellent

protection against physical damage and maintaining the integrity of

the internal environment. The interior is lined with a smooth,

non-reactive surface to prevent any interaction between the chamber

and the tested components. The insulation used is top-notch,

minimizing heat transfer between the different temperature zones

and ensuring rapid and accurate temperature changes.

- The door of the chamber is engineered for a tight seal. It is

equipped with a reliable locking mechanism and a high-quality

gasket that can withstand the pressure differentials caused by

rapid temperature changes. The door also features a clear viewing

window, allowing users to monitor the testing process without

disturbing the internal temperature conditions.

- Precision Temperature Control Systems

- The temperature control system is highly advanced and accurate. It

can achieve a wide temperature range, usually from -60°C to +180°C.

The system utilizes a combination of powerful heating and

refrigeration elements, along with a sophisticated feedback loop

and multiple temperature sensors strategically placed within the

chamber. This allows for rapid temperature transitions, often

within minutes, which is crucial for replicating real-world thermal

shock conditions.

- The temperature uniformity within the chamber is maintained within

±1°C, ensuring that all parts of the sample are exposed to a

consistent temperature environment during each phase of the test.

The system also has built-in safety features to prevent overheating

or overcooling, protecting both the samples and the chamber itself.

- Efficient Airflow and Transfer Mechanisms

- The chamber is equipped with a high-efficiency airflow system that

ensures rapid and uniform temperature distribution. The airflow is

carefully designed to minimize temperature gradients and ensure

that the samples are exposed to the desired temperature as quickly

as possible. Additionally, the transfer mechanism between the hot

and cold zones is engineered for speed and reliability. It allows

for seamless movement of the samples from one temperature extreme

to the other, without significant temperature fluctuations during

the transfer process.

- The transfer basket or rack used to hold the electronic components

is made of heat-resistant and non-conductive materials, preventing

any unwanted heat transfer or damage to the samples. It is also

designed to be easily removable for convenient loading and

unloading of the test specimens.

- Volume and Dimensions: The chamber can be customized in terms of volume and dimensions

to accommodate different sizes and quantities of electronic

components. Whether it's small microchips or large circuit board

assemblies, the interior space can be optimized to ensure efficient

testing. The external dimensions are also designed to fit into

various laboratory or production facility setups.

- Temperature Range: As mentioned, the chamber can operate from -60°C to +180°C. This

wide range is essential for testing a vast array of electronic

products. For example, components used in automotive electronics

may need to withstand cold starts and engine heat, while those in

aerospace applications must endure the extreme cold of space and

the heat generated during re-entry.

- Temperature Transition Rate: The chambers can achieve rapid temperature transitions, typically

within 5 to 10 minutes. This rate is crucial for accurately

simulating real-world thermal shock conditions. For instance, a

consumer electronic device that is quickly moved from a cold

air-conditioned room to a hot outdoor environment should be able to

handle such rapid temperature changes without malfunctioning.

- Uniformity and Stability: The temperature uniformity within the chamber is maintained

within ±1°C, ensuring that all parts of the tested component

experience a consistent thermal environment. The stability of the

temperature in each zone is excellent, with minimal fluctuations

over time, allowing for accurate and repeatable testing.

- Accurate Simulation of Thermal Shock Conditions

- The main function of these chambers is to precisely replicate the

thermal shock conditions that electronic components face. By

rapidly changing the temperature, it allows manufacturers to

evaluate how well the materials and components can handle the

stress. For example, testing a soldered joint on a circuit board

under thermal shock can reveal if it will crack or separate due to

the expansion and contraction of different materials.

- The ability to program complex temperature profiles and cycling

patterns is also a valuable function. This allows for the

simulation of different real-world scenarios, such as the daily

temperature fluctuations in a desert environment or the temperature

changes during the startup and shutdown of an industrial machine.

By testing under these various conditions, manufacturers can ensure

that their products are robust enough to handle any thermal shock

they may encounter.

- Enhanced Product Quality and Reliability

- Through rigorous thermal shock testing, manufacturers can enhance

the quality and reliability of their electronic products. By

identifying and addressing potential weaknesses early in the design

or production process, they can reduce the risk of field failures.

For example, if a capacitor fails during thermal shock testing, the

manufacturer can modify the design, such as improving the

dielectric material or the encapsulation, to improve its

durability. This leads to increased customer satisfaction and a

lower cost of warranty claims and product recalls.

- The test chambers also help in optimizing product design. By

understanding how different materials and components respond to

thermal shock, engineers can make more informed decisions about

material selection and component placement. This can result in more

efficient and reliable product designs, ultimately giving companies

a competitive edge in the market.

- Compliance with Industry Standards and Regulations

- The electronics industry is highly regulated, and many standards

and regulations require thermal shock testing. These chambers are a

reliable tool for ensuring compliance. For example, components used

in military and aerospace electronics must meet strict thermal

shock resistance requirements. By using these chambers to conduct

tests in accordance with industry standards, manufacturers can

prove that their products meet the necessary criteria, facilitating

market access and building trust with customers and regulatory

bodies.

- Regulatory bodies rely on accurate test results obtained from such

chambers to enforce safety and quality regulations. It serves as a

means for certifying that electronic components can withstand the

thermal stress they may encounter during their normal use, thereby

protecting consumers and maintaining the integrity of the market.

- Stringent Manufacturing Process

- The Customized Thermal Shock Test Chambers for the Electronics

Industry are manufactured under strict quality control procedures.

Each component, from the heating and refrigeration units to the

temperature sensors and insulation materials, is carefully sourced

and inspected for quality and performance. The assembly process is

carried out by highly trained technicians in a clean and controlled

environment, ensuring the proper installation and functionality of

all parts.

- The calibration of the temperature sensors and control systems is a

critical and regular part of the manufacturing process. It is

performed using traceable reference standards to guarantee the

accuracy and reproducibility of the test results. Rigorous quality

audits and inspections are conducted at various stages of

production to maintain the highest level of product quality.

|