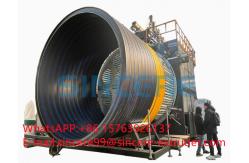

PE HDPE PP Winding Spiral Pipe Extrusion Line Hollow Wall

|

PE HDPE PP Hollow Wall Spiral Winding Pipe Extrusion LineBasic Info.Model NO. SMSG3600, SMSG3000, SMSG4000, SMSG2000, 1000 Automation Automatic Computerized Computerized Certification CE, ISO9001:2008 Customized Customized Condition New After-sales Service Provide Installation and Debug Service HDPE Pipe Machine Types Hollow Wall Winding Pipe, Square Tube Winding Pipe Delivery Conditions Fob CIF CIP Processing Period 40-90 Working Days Delivery Period 30days Technical Support Permanent Electrical Appliances ABB, Siemese, Omron, Shneider Output 300-1500kg/H Spiral Winding Pipe Line 6-1 Single-Screw Extruder 33:1 or 38:1 Spiral Winding Pipe Line 6-2 HDPE Square Profile or Rectangular Tube Machine Spiral Winding Pipe Line 6-3 Vacuum Water Tank, Haul-off Machine, Cutting Machi Spiral Winding Pipe Line 6-4 Spiral Winding Machine, Spirally Wound Machine Spiral Winding Pipe Line 6-5 Siemens Electrical System with Touching Screen Spiral Winding Pipe Line 6-6 Pipe Shredder, Crusher and Pelletizer Spiral Winding Pipe Machine Line Hollowness Wall Winding Pipe Production Line HDPE Water Drainage Pipe Machine HDPE Spiral Winding Pipe Machine Transport Package Stretch Film and Wooden Pallet, Wooden Packing Specification Diameters 200-4000, Structural hollow wall pipes Trademark Sincere Machinery Origin Qingdao, China HS Code 8477209000 Production Capacity 50 SetsYear Product Description:The HDPE Spiral Pipe Making Line is equipped with an extruder output of 200-1000kg/h, making it ideal for small to large scale manufacturing. It also features an automatic coiling method, which simplifies the handling of the pipe, making it easier for operators to handle and transport. The Spiral Pipe Extrusion Line can produce spiral pipes with a diameter range of 200-4000mm, making it adaptable to a wide range of applications. The unique co-extrusion technology used in our machinery ensures that the pipes produced are of high quality, with smooth internal and external surfaces, excellent dimensional accuracy, and high impact resistance. The total power of our HDPE Spiral Pipe Making Line ranges between 200-500kW, depending on the model. The machinery is highly efficient, with low power consumption, making it a cost-effective solution for your production line. Our Spiral Pipe Extrusion Line is designed with ease of use in mind, with a user-friendly interface and easy-to-use controls. Operators can easily monitor and adjust the production process to ensure that the pipes produced meet the required specifications. In summary, our HDPE Spiral Pipe Making Line is an excellent investment for any business looking to produce high-quality spiral pipes efficiently, accurately, and cost-effectively. With its high extruder output, automatic coiling method, wide diameter range, and user-friendly design, our Spiral Pipe Extrusion Line is the perfect solution for your manufacturing needs. Features:

This is a Large Diameter Spiral Tube Extrusion Line that provides Continuous Spiral Pipe Production Line, ensuring high-quality and efficient production of spiral pipes with diameters ranging from 200mm to 4000mm. With a production speed of 0.5m/min up to 10m/min, this product guarantees a fast and uninterrupted production process. Additionally, it features an Automatic Coiling Method, making it easier to handle the produced pipes. The total power required is between 200kW to 500kW, depending on the model. Lastly, the weight of the product varies according to the chosen model. Technical Parameters:

Applications:With a weight that varies depending on the model, this production line is designed to accommodate a range of different pipe diameters, ranging from 200mm to 4000mm. This makes it ideal for use in a variety of different industries, including sewage treatment, drainage systems, and more. Thanks to its high production speed of between 0.5-10m/min, the Sincere Plastic HDPE Spiral Winding Tube Production Line is perfect for those who need to produce large quantities of pipe quickly and efficiently. This is further aided by its total power output of between 200-500kW, which ensures that it can handle even the most demanding of production schedules. In addition to its impressive production speed and power output, this production line also boasts an extruder output of between 200-1000kg/h. This ensures that you can produce a large quantity of high-quality pipe in a short amount of time, helping to streamline your production process and reduce waste. Overall, the Sincere Plastic HDPE Spiral Winding Tube Production Line is an excellent choice for those who require a Continuous Spiral Pipe Production Line that is both efficient and reliable. With its high production speed, extruder output, and power output, it is sure to meet the needs of even the most demanding production schedules. Whether you need to produce pipe for sewage treatment, drainage systems, or any other application, this production line is sure to get the job done. HDPE extrusion spiral winding pipes machine, Hollowness wall spiral winding corrugated pipes HDPE extrusion production machine lines.Our cooperation process:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: HDPE Spiral Pipe Extrusion Line PP Spiral Pipe Extrusion Line HDPE Winding Pipe Extrusion Line | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

HDPE Spiral Pipe Extrusion Line With High Capacity |

|

HDPE PP Spiral Pipe Extrusion Line 200-600 800-2400 1200-4200mm |

|

HDPE PP PPH Spiral Pipe Production Line Extrusion Line |

|

HDPE PPH PP Spiral Pipe Extrusion Line 200-1000kg/h |

|

PE PP HDPE Spiral Winding Pipe Making Machine |

|

HDPE Spiral Pipe Extrusion Line Large Diameter Spiral Tube Production Line |