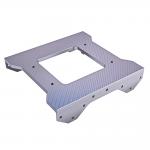

High Precision OEM Custom CNC Machining Milling Parts Aluminum Metal Fabrication Services

|

|

The development trend of CNC (numerical control) milling parts processing industry is mainly reflected in the following aspects:

Technological innovation and intelligence: CNC parts processing will pay more attention to improving processing accuracy and efficiency. By optimizing CNC systems and machine tool design, the needs of high-precision industries such as aerospace and equipment can be met. Intelligence and automation will also become important development directions. By introducing intelligent control systems, robotics technology and artificial intelligence algorithms, the automation and intelligence of the processing process can be realized.

Multi-axis processing and composite processing: With the increase in the demand for complex parts processing, multi-axis processing technology will be more widely used. High-end equipment such as five-axis linkage CNC machine tools will become the mainstream of CNC parts processing, realizing efficient and high-precision processing of complex surfaces. Composite processing technology, that is, integrating multiple processing methods such as turning, milling, drilling, and grinding on one machine tool, is also an important development direction.

Green manufacturing and sustainable development: CNC parts processing will pay more attention to the use of environmentally friendly materials and green manufacturing processes to reduce the impact on the environment. The circular economy model will also be actively promoted to achieve resource conservation and recycling through the recycling and remanufacturing of waste parts.

Digitalization and networking: Digital factories will become an important development direction in the field of CNC parts processing. By building digital factories, the production process can be digitalized, networked and intelligently managed to improve production efficiency and flexibility. Remote monitoring and maintenance technologies will also be applied. High-speed, precision, intelligent and miniaturized machine tools: With the widespread application of light alloy materials in the automotive, aerospace and other industries, high-speed machining has become an important development trend in manufacturing technology. High-speed machining has the advantages of shortening machining time, improving machining accuracy and surface quality. The high-speed of machine tools requires new CNC systems, high-speed electric spindles and high-speed servo feed drives, and optimized and lightweight machine tool structures.

Integrated growth of automation and robotics: The increasing application of automation and robotics in the field of CNC machining effectively supplements the shortage of human resources, improves production efficiency and quality, and reduces dependence on manpower.

These trends indicate that the CNC milling parts processing industry will continue to develop in the direction of higher precision, greater flexibility and stronger competitiveness.

FAQ:

1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week. |

| Product Tags: Custom CNC Machining Milling Parts Aluminum Metal Fabrication ServicesCNC Milling Parts High Precision CNC Machining Milling Parts |

|

±0.01mm Precision CNC Milling Parts CNC Five-axis Machining Center Five-axis Linkage CNC Milling Precision Parts Mass Production |

|

Micron-level CNC Milling Parts Stainless Steel CNC Turning And Milling Parts Precision Parts For Model Aircraft Engines |

|

Drone Landing Gear Lightweight Aviation CNC Milling Aluminum Parts Aluminum Bracket |

|

Milling And Drilling Integrated CNC Parts End Milling Processing Mobile Power Housing |

|

Customized Mobile Power Housing CNC Machining Parts Communication Equipment 5G Base Station Heat Sink |

|

Stainless Steel CNC Turning and Milling Composite Processing Parts Rapid Proofing for Engine Clutch Bell Housing |