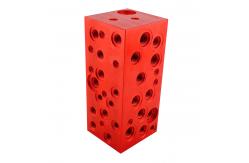

Custom Hydraulic Manifolds CNC Machining Anodized Solenoid Valve Manifold

|

|

Hydraulic valve blocks are an important component in hydraulic systems. They are usually used to control and regulate fluid pressure, flow and direction. Due to their reliability and functionality, hydraulic valve blocks are widely used in multiple industries. Here are some of the main application areas:

Construction and earthwork engineering: Manufacturing: Automobile and automotive parts manufacturing: Aerospace: Ship and marine engineering: Energy industry: Forestry and wood processing: Agricultural machinery: Transportation: Defense and military:

The application of hydraulic valve blocks in the above industries improves the automation and operating efficiency of mechanical equipment, while also ensuring the stability and safety of the system.

FAQ Q1: Are you a manufacturer or trading company of custom CNC

mechanical parts?

Q2: What is the order quantity of hydraulic manifold valves, CNC

parts, machined parts, engineering plastic parts, etc.

Q3: When is the delivery date of hydraulic manifold valves, CNC

parts, machined parts, engineering plastic parts

Q4: How to order hydraulic manifold valves, CNC parts, machined

parts, engineering plastic parts, etc. 3. Make samples for your review.

Q5: What is the quality of your hydraulic manifold valves, CNC

parts, machined parts, engineering plastic parts, etc.?

Q6: How about the shipping method? |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Custom Hydraulic Manifolds Hydraulic Manifolds CNC Machining Anodized Solenoid Valve Manifold | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Passivation Hydraulic Manifold for Medical Equipment Optimal Design Maximum Flow Rate of 180L/min and OEM Acceptance |

|

Zinc and Nickel Alloy Custom Hydraulic Manifolds 100% Tested for Heavy Duty Applications |

|

Zinc And Nickel Alloy Hydraulic Valve Block for Precise Hydraulic Control and Functionality |

|

Aluminum Hydraulic Manifold Valve Block for Vehicle Hydraulic System Modification 100% Tested and OEM Non-Standard |

|

Customized Settings Steel Hydraulic Valve with Max 350bar Work Pressure and High Performance |

|

Customizable Hydraulic Manifold For Parallel Circuit Configuration 100% Tested OEM ODM Servo Hydraulic Valve |