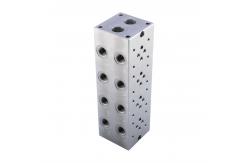

Aluminum Alloy Al6061 Hydraulic Cylinder Valve Block CNC Machining Manifold Block

|

|

Hydraulic Valve Custom Aluminum Alloy Al6061 Hydraulic Cylinder Control Valve Block Cnc Machining Manifold Block

The hydraulic manifold is an important component in the hydraulic system. It is mainly used to distribute hydraulic oil to various parts of the system. The following are the main features of hydraulic manifolds and their benefits:

feature Integration: Hydraulic manifolds usually integrate multiple hydraulic components, such as valves, pressure gauges, sensors, etc. Complex design: The manifold is designed with complex oil passages inside to ensure that hydraulic oil can be efficiently and accurately distributed to each actuator. Material: Usually made of high-strength, high-pressure-resistant metal, such as steel or aluminum alloy. Sealing performance: High sealing performance is required to prevent hydraulic oil leakage. Connection method: Use threaded connection, flange connection or other forms of quick connectors to connect to other parts of the system.

benefit Reduced leak points: Because multiple components are integrated together, hydraulic manifolds can significantly reduce potential leak points compared to discrete components. Save space: The integrated design can reduce the number of pipes and connections, thereby saving installation space. Improve efficiency: By optimizing the oil circuit design, the hydraulic manifold can reduce fluid resistance and improve system efficiency. Easy maintenance: Centralized component layout makes inspection, maintenance and replacement more convenient. Reduced costs: Reducing the use of connections and tubing reduces the cost of manufacturing the system. Improve reliability: The integrated design reduces failure points and improves the reliability of the entire hydraulic system. Aesthetics: Hydraulic manifolds can give the hydraulic system a neater, more orderly appearance.

The design and application of hydraulic manifolds need to be customized to specific hydraulic system needs to ensure optimal performance and stable operation of the system. During the design and manufacturing process, factors such as the system's pressure level, working environment, media type, etc. also need to be considered.

|

| Product Tags: Hydraulic Cylinder Valve Block Hydraulic Cylinder Valve Block |

|

Passivation Hydraulic Manifold for Medical Equipment Optimal Design Maximum Flow Rate of 180L/min and OEM Acceptance |

|

Zinc and Nickel Alloy Custom Hydraulic Manifolds 100% Tested for Heavy Duty Applications |

|

Zinc And Nickel Alloy Hydraulic Valve Block for Precise Hydraulic Control and Functionality |

|

Aluminum Hydraulic Manifold Valve Block for Vehicle Hydraulic System Modification 100% Tested and OEM Non-Standard |

|

Customized Settings Steel Hydraulic Valve with Max 350bar Work Pressure and High Performance |

|

Customizable Hydraulic Manifold For Parallel Circuit Configuration 100% Tested OEM ODM Servo Hydraulic Valve |