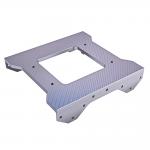

Stainless Steel Aluminum CNC Milling Parts Precision Rapid Prototyping Services

|

|

CNC Milling Parts Stainless Steel Aluminum CNC Parts Precision Rapid Prototyping Services

CNC (Computer Numerical Control) milling is a common machining technology used to produce complex metal or non-metal parts. The characteristics of CNC milled parts can be described from many aspects, and the following are some of the main characteristics:

Shape and complexity: Dimensional accuracy: Surface finish: Material diversity:

FAQ Q1: What kind of CNC machining services do you offer?A1: CNC machining is also known as computer numerical control machining. We offer the following machining services: milling, turning, drilling, threading, tapping, EDM and wire-cutting, custom surface treatments, prototyping, small batch or single-use parts machining. From prototype to production, from 1 to 10,000 pieces, we offer fast turnaround CNC machining for your custom metal and plastic parts, the fastest delivery time can be within 3 days. Q2: What are your CNC machining capabilities? A2: We have 3000 square meters of CNC machining workshop. With 60+ skilled employees and more than 20 high-performance CNC machines, it maintains 24/7 operations and can deliver more than 400 machining projects and 30,000+ machined parts per month. Q3: What is the cost of CNC machining parts? A3: Our engineering and sales teams will provide one-to-one quote support for your project. In general, for similar parts, the machining cost of CNC lathes is 15% lower than that of standard 3-axis CNC milling. In contrast, the cost of 5-axis machining increases, and the cost of 5-axis linkage milling is higher than that of a 5-axis machine (also known as 3+2 milling) by 20%, about twice as much as a standard 3-axis milling machine. Q4: What is the maximum size range of your machine travel? A4: Max size of the 3-axis milling is 1500×808×635(mm); Max size of the 5-axis milling is 1016×635×635(737)(mm),Work table diameter is Φ635 mm . Q5: What kind of surface finish does CNC machining leave behind? A5: After machining, there are slightly tool marks on the part surface which is called “machining marks” or “milling marks” surface finishing. The standard machining surface roughness(Ra) is 1.6-3.2μm. We can improve to 0.8-1.6μm or better 0.2-0.8μm but it takes more operation time and cost. |

| Product Tags: CNC Milling Parts Precision Stainless Steel CNC Milling Parts Precision Rapid Prototyping Services |

|

±0.01mm Precision CNC Milling Parts CNC Five-axis Machining Center Five-axis Linkage CNC Milling Precision Parts Mass Production |

|

Micron-level CNC Milling Parts Stainless Steel CNC Turning And Milling Parts Precision Parts For Model Aircraft Engines |

|

Drone Landing Gear Lightweight Aviation CNC Milling Aluminum Parts Aluminum Bracket |

|

Milling And Drilling Integrated CNC Parts End Milling Processing Mobile Power Housing |

|

Customized Mobile Power Housing CNC Machining Parts Communication Equipment 5G Base Station Heat Sink |

|

Stainless Steel CNC Turning and Milling Composite Processing Parts Rapid Proofing for Engine Clutch Bell Housing |