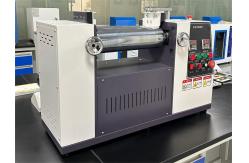

Product Description

-The two roll rubber open mill rubber mixing machine is a type of

rubber processing equipment that is used to mix and process rubber

compounds. It consists of two horizontally placed rolls that rotate

in opposite directions at different speeds.

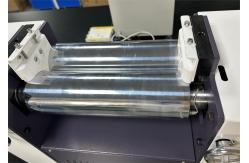

-The rubber material is fed into the gap between the rolls, which

are adjustable to control the thickness of the sheet being

produced. The rolls are heated and cooled to control the

temperature of the rubber compound during mixing.

-The open design of the machine allows for easy access and

monitoring of the mixing process.

-This type of machine is commonly used in the rubber industry for

producing various rubber products such as tires, belts, hoses, and

seals.

-A rubber mixing machine with exposed rollers used in rubber

factories to prepare plasticized rubber, mixed rubber, or

heat-cured and molded.

-The main working parts are two hollow rollers or drilling rollers

that rotate inward in different directions.

-The one installed on the operator's side is called the front

roller, which can be moved back and forth horizontally by manual or

electric action to adjust the roller distance to meet the operating

requirements; The rear roller is fixed and cannot move back and

forth.

-The size of the two rollers is generally the same, and they rotate

relative to each other at different speeds.

-The raw rubber or rubber material is drawn into the gap between

the two rollers with the rotation of the rollers, and is subjected

to strong shearing to achieve the purpose of mastication or mixing.

Mills are also used in sectors such as plastics processing

Detailed Photos

Product Parameters

| Product Name | Open Mill Rubber Mixing Machine |

| Item model | GC-KLJ-3 |

| Conrtol mode | Keystoke Control |

| Machine size | 750*380*×600mm |

| Spacing display method | Scale |

| Roller width | 300mm |

| Roller hardess | 50 ~ 60HRC |

| Roller Handling | Mirror Polished Chrome |

| Rotating speed | 10-40r/min |

| Roller temperature | Normal temperature/normal temperature -250 ºC |

| Temperature uniformity | 2.5 °C |

| Special function | Emergency stop |

| Total weight | ≈128kg |

| Power | AC220V, 2.2KW |