Melt Flow Resin Plastic Mfi Tester Checking Machine High Precision

|

|

High Precision Melt Flow Testing Machine For Plastic And Resin Test -The Automatic melt flow index tester is a euqipment used to

measure the melt flow index (MFI) of polymer and engineering

materials. The MFI is a measure of the flow properties of a

polymer when it is melted under specified conditions.

Product advantage:

-1.Multi-stage (2-stage) temperature control method, 2 sets of platinum resistance sensors, 2 heating jackets for independent temperature control, high-precision intelligent PID control, the heating slope or heating speed is adjustable

-2.The temperature resolution is 0.1℃, the temperature uniformity is 0.2℃, the temperature fluctuation within 24 hours does not exceed 0.5℃, and the displacement sensor resolution is 0.001mm.

-3.Temperature over-temperature protection device Integrated manual and automatic cutting, cutting time (0~999) and cutting times (0~999) can be set arbitrarily

-4.When testing, you can choose the mass method, the volume method, or both testing methods at the same time, and the flow rate ratio can be calculated. Both methods start testing when the piston rod moves to a certain position. It has a built-in temperature stabilization alarm, and adds a 240-second (GB3682 stipulated) material preheating second countdown. After the countdown is over, a prompt sound will sound, and the preheating time such as American Standard (ASTM) can also be set.

-5.A variety of plastic material melt index test conditions are built-in, which is convenient for customers to call up and use at any time, reducing tedious workload, and storing the last test conditions and results. Built-in micro printer for easy printing of test data

-6.High-precision touch screen controller, 7-inch touch screen, can store and print recent test conditions and data. The settings of the test print menu include test time (system default), operator, material name, test method, test conditions (temperature, weight) Weight, cutting time interval), test result data, test result artificial judgment OK or NG, etc.

-7.The RS232 interface or USB interface is reserved to connect to the computer, and the instrument operation can be controlled through the computer and the test data can be transmitted and saved to the computer.

-8.The weight can be loaded manually or the ball screw can be driven by a stepper motor to automatically control the rise or fall of the top-loaded weight.

|

||||||||||||||||||||||||||||||||

| Product Tags: Resin plastic mfi tester Melt Flow plastic mfi tester Resin mfi checking machine |

|

Compact Portable Spectrophotometer Colorimeter For Plastic Rubber Material |

|

Vulcanized Rubber DIN 53512 Elasticity Testing Machine For Rubber Industry |

|

Six Racks Plastic HDT Vicat Tester Softening Point Deformmation Test Machine |

|

High Presicion Touch Screen DSC Differential Scanning Calorimeter Sensor 100A |

|

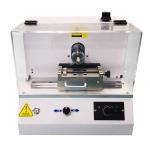

Woodworking Power Sample V Notch Cutter Machine For Plastic Testing |

|

Full Automatic Plastic Testing Equipment Sample V Notch Cutting Machine 220V |