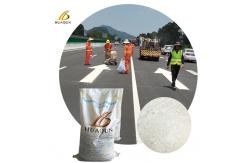

Reflective Thermoplastic Road Marking Paint with 20% Glass Beads

for Pavement Marking

Description

What is thermoplastic road marking paint?

Thermoplastic road marking paint, also called hot melt marking

paint, is a specialized type of powder paint that is made from

thermoplastic materials. Thermoplastic paint is composed of a

mixture of resin, pigments, glass beads, fillers, and various

additives.

Thermoplastic powder paint requires specialized equipment like a

preheater machine – hot melt machine which will heat it to 200 °C

(392 °F) to melt the powder. When heated, this material becomes

liquid and can be applied to road surfaces. Once it cools and

solidifies, it forms a durable and long-lasting marking on the

road.

The unique characteristic of thermoplastics is their ability to

soften when heated and solidify when cooled. This property allows

for easy application and ensures a long-lasting and robust finish

on road surfaces.

Technical Specification

| Density(g/cm3) | 1.8-2.3 |

| Softening point (℃) | 90-125 |

| Compressive Strength(MPa) | ≥12 |

| Glass bead content(%) | 0-30% |

| Liquidity | 35±10 |

| Packing | 25kg/bag |

| Color | White/Yellow/Blue/Red/Green/Customized |

| Executive standard | JT/T280-2004/AASHTO/BS3262/Customized |

| Appearance | Powder |

| Construction temperature | 180℃-220℃ |

| Whiteness | 70-85(Customized) |

| Inverse coefficient | 50-550 |

| Warranty | 12 months |

| Storage Method | Avoid light and moisture |

| Packing Size | 45×70×5CM |

Product Advantage:

1. Higher adhesive strength: Special elastomer is added in our

recipe of thermoplastic road marking paint in order to improve the

adhesive strength.

2. Stronger crack resistance: Our recipe compounded a special

additive which is seasoned with the temperature.Thus it avoids

possible deformation of the melted film caused by nature

temperature variation.

3.Bright color: Our recipe introduced high quality color filler

with reasonable mixture proportion. And it helps thermoplastic

paint lasts for years without color change.

4.Enhanced wet night visibility.

5. Immediate retroreflectivity.

Formula Customized

| Customized Formula |

| Customized Formula | Content(Customized range) | Characteristics |

| C5 Resin | 10%-22% | Fluidity Toughness Hardness Adhesion |

| Titanium Dioxide | 0.5-10% | 0.5%-30% |

| Premixed glass beads | 0%-30% | Reflective after surface wear |

| Calcium Carbonate Sand | 30%-80% | Whiteness Wear-resistant Hardness |

| PE Wax | 1%-1.5% | Cold and heat resistant |

| EVA | 0.5%-1% | Crack resistance |

| Plasticizer | 1%-1.5% | Toughness |