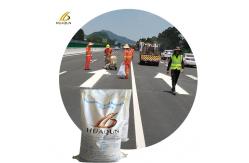

Long-Lasting and Wear-Resistant Thermoplastic Paint for Road

Marking Quick Drying and Easy Application

Product

Description

Thermoplastic paint is a type of paint that is heated to a molten

state for application. It solidifies quickly upon cooling, forming

a durable and wear-resistant coating, often used for road markings

due to its high visibility and long lifespan.Key Components:- Resins (Binders) – Provide adhesion and structure.

- Pigments – Provide color and opacity.

- Glass Beads – Enhance reflectivity for visibility.

- Plasticizers – Increase flexibility and prevent cracking.

- Fillers – Adjust texture and durability.

- Solvents (Optional) – Help with application, though not typically used in

thermoplastic paint.

- Additives – Improve performance, such as UV resistance or anti-aging

properties.

Advantages of Hot Melt Paint: - Durability: Long-lasting and resistant to wear and harsh conditions.

- Quick Drying: Minimizes road downtime and allows immediate use.

- High Visibility: Reflective properties improve safety, especially at night.

- Easy Application: Fast and efficient with specialized equipment.

- Weather Resistant: Stands up to extreme weather conditions and UV exposure.

- Cost-effective: Lower maintenance and long lifespan reduce overall costs.

- Environmental Friendly: Low VOCs and minimal solvents.

- Flexibility: Adapts to surface movements and can be used for various

applications.

- Reversibility: Can be easily replaced or removed without surface damage.

- Customizable: Available in multiple colors for specific needs.

Specification | Gravity(g/㎥) | 2.1g/㎥ | | Color | Yellow, Orange, Red and etc. | | Heating Temperature | 180℃-220℃ | | Softening Point(℃) | 110℃ | | Coating Appearance | No wrinkles, dots, blisters, cracks,fall-out&stick tyres | | Drying Time(min) | Within 3 minutes | | Chroma Performance | Reverse materials(white) | | Compressive Strength(Mpa) | 26 | | Abrasive Resistance(mg) | 42 | | Alkali Resistance | Great (in saturated solution of calcium hydroxide for 24 hours | | Glass Beads(%) | 19% | | Fluidity(s) | 40s | | Coating Resistance | Resis -10℃ for 4 hours | | Package | 25kg/bag, by plastic woven bag. One 20’container can load Max 26

tons | | Heat Resistance | Under 200℃-220℃ for hours | | Material | C5 Petroleum Resin, CACO3, Wax, Glass Beads, EVA, PE and so on. | | Application | Road marking, straight line, dotted line, curve, oriented

arrow,letter and etc. | | Water Resistance | Great (in water for 24 hours) |

Application Process

- Pre-treatment: The surface to be painted, such as a road surface, must be clean,

dry, and free of dust, oil, and loose particles. This is usually

achieved through methods like sandblasting or power washing.

- Heating: The thermoplastic paint is heated in a special kettle or melter to

a temperature typically between 180°C and 220°C (356°F - 428°F),

depending on the specific formulation. At this temperature, the

paint becomes a fluid, viscous liquid that can be easily applied.

- Application: It is then applied using equipment such as a screed applicator or

a spray gun. For road markings, a screed is commonly used to spread

the molten paint evenly at a specific thickness. Glass beads are

often sprinkled onto the wet paint immediately after application to

enhance retroreflectivity, making the markings more visible at

night.

- Cooling and Solidification: Once applied, the paint cools rapidly due to the lower temperature

of the substrate and the surrounding environment. As it cools, it

solidifies into a hard, durable coating within a short period,

usually within a few minutes.

Technical Specification

| Density(g/cm3) | 1.8-2.3 | | Softening point (℃) | 90-125 | | Compressive Strength(MPa) | ≥12 | | Glass bead content(%) | 0-30% | | Liquidity | 35±10 | | Packing | 25kg/bag | | Color | White/Yellow/Blue/Red/Green/Customized | | Executive standard | JT/T280-2004/AASHTO/BS3262/Customized | | Appearance | Powder | | Construction temperature | 180℃-220℃ | | Whiteness | 70-85(Customized) | | Inverse coefficient | 50-550 | | Warranty | 12 months | | Storage Method | Avoid light and moisture | | Packing Size | 45×70×5CM |

|