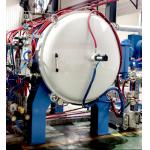

highest temperature 2200 degree Vacuum Hot Press Sintering Furnace

|

Detailed Product Description

|

Specification Usage: The equipment is mainly used for colleges and universities,

scientific research units for metal compounds, ceramics, inorganic compounds, nanomaterials, etc., under the condition of vacuum or protective atmosphere for

pressure heating and sintering processing, in order to obtain

consistent products, such as the production of high-precision silicon nitride ceramic bearings and silicon nitride ceramic substrate.

Features:(1) Double SUS304 furnace structure, cooling water through the

middle, effectively reduce the surface temperature of the furnace

body to reduce high temperature damage, reduce the impact on the

environment; (2) frame type double column support structure, using profile

welding, overall processing, to ensure the reliability of

equipment; (3) the use of thermal insulation materials and thermal insulation

structure, low thermal conductivity, good thermal insulation

effect, even at a high temperature can effectively isolate heat,

save energy consumption; (4) Wide temperature range, heating elements of various options,

such as graphite, molybdenum, tungsten, tantalum, in the

appropriate protective atmosphere, the temperature can reach 2800℃,

can adapt to the hot pressing sintering of different materials; (5) Diversified vacuum system configuration, choose different

levels of vacuum according to the process; (6) Without charging and releasing system, you can choose hot

pressing sintering in vacuum environment, also can choose hot

pressing sintering in inert atmosphere or reducing atmosphere; (7) Humanized configuration, both manual operation, can also

achieve one-button intelligent operation; (8) This Furnace can meet multi-purposes, can be used as a simple

vacuum or atmosphere sintering furnace; (9) diversified types, vertical upper discharge, vertical side door

discharge, one-way pressure, two-way pressure and so on, arbitrary

choice; (10) This product accepts non-standard customization. Product parameter: Title goes here.1) Double SUS304 furnace structure, cooling water through the

middle, effectively reduce the surface temperature of the furnace

body to reduce high temperature damage, reduce the impact on the

environment; 2) frame type double column support structure, using profile

welding, overall processing, to ensure the reliability of

equipment; Title goes here.3) the use of thermal insulation materials and thermal insulation

structure, low thermal conductivity, good thermal insulation

effect, even at a high temperature can effectively isolate heat,

save energy consumption; 4) Wide temperature range, heating elements of various options,

such as graphite, molybdenum, tungsten, tantalum, in the

appropriate protective atmosphere, the temperature can reach 2800℃,

can adapt to the hot pressing sintering of different materials; Title goes here.5) Diversified vacuum system configuration, choose different levels

of vacuum according to the process; 6) Without charging and releasing system, you can choose hot

pressing sintering in vacuum environment, also can choose hot

pressing sintering in inert atmosphere or reducing atmosphere; 7) diversified types, vertical upper discharge, vertical side door

discharge, one-way pressure, two-way pressure and so on, arbitrary

choice; Company Profile We are not your supplier,but your parter and supply the whole

thermal treatment furnace solutions with strong R&D research

team,stable supply chain with 14+ years experience under the strict

ISO9001:2015 quality management system. The State Intellectual Property Office of the People's Republic of

China (SIPO), in accordance with the Patent Law of the People's

Republic of China, examined and granted our patent rights: Patent for high temperature graphitization furnace:Patent for high temperature vacuum hot pressure furnace:Patent for high temperature continuous furifing graphitization furnace:Patent for carbonization sintering furnace:Patent for bottom discharge graphitization furnace:Patent for carbon fiber continuous furnaceProduction process Customers Photos Customer cooperation cases: |

Related Products

|

|

Si2oz silicon oxide sintering furnace |

|

|

high quality China factory produced Si2oz sintering furnace for Silicon oxide mateirals |

|

high quality factory price 1600 degree MIM debinding Sintering Furnace for high precision metal parts |

|

1600 degree MIM debinding Sintering Furnace for high precision metal parts |

|

|

China factory price OEM CE ISO Highest temperature 2300 degree resistance heating vacuum Silicon Carbide Sintering Furnace |

|

2400 degree JT-RYL300 300Ton Vacuum Hot Press Sintering Furnace for Ceramics material |

Email to this supplier