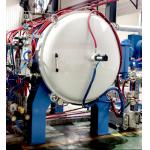

2400 degree High Temperature Sintering Furnace under argon and Nitrogen

|

|

High Temperature Sintering Furnace

Application:

vacuum/atmosphere sintering of cemented carbide, copper-tungsten alloy, tungsten, molybdenum, alnico-cobalt permanent magnet, SmCo5, Sm2Co17, Ndfeb, titanium alloy and other alloy materials.

Product Advantage:

The high temperature sintering furnace is a performance intelligent electric furnace which is specially suitable for cemented carbide industry (process permits can also be applied to other industries), and the engineers and technicians of our factory digest and absorb the temperature measurement, temperature control technology, intelligence, new material technology and furnace design technology at home and abroad. The intermediate frequency induction sintering furnace produced by our factory is an intermittent gas (vacuum) protection furnace. According to the needs of sintering process time, a single set of power supply can be configured with multiple electric furnaces, which are heated by electricity and cooled by electricity respectively for a single furnace to achieve continuous work.

Features:

Ultra-high temperature furnace body within 2400℃ can fully meet the sintering of various materials. Using digital display intelligent temperature control system, automatic precision to complete the temperature measurement and temperature control process, the system can be heated according to the given temperature curve, and can store 20 pieces of a total of 400 different process heating curve. Adopt internal circulation pure water cooling system, digital flow monitoring system;High performance medium frequency contactor is used for automatic conversion of furnace body. Comprehensive PLC water, electricity, gas automatic control and protection system.

Product Specification:

|

|

|

Si2oz silicon oxide sintering furnace |

|

|

high quality China factory produced Si2oz sintering furnace for Silicon oxide mateirals |

|

high quality factory price 1600 degree MIM debinding Sintering Furnace for high precision metal parts |

|

1600 degree MIM debinding Sintering Furnace for high precision metal parts |

|

|

China factory price OEM CE ISO Highest temperature 2300 degree resistance heating vacuum Silicon Carbide Sintering Furnace |

|

2400 degree JT-RYL300 300Ton Vacuum Hot Press Sintering Furnace for Ceramics material |