CaF2 Germanium Optical Window Optical Infrared Lens for Thermal

Imaging

Glass Material- Calcium Fluoride (CaF2):

- Composition: A crystalline form of fluoride with high optical transparency.

- Properties: Low dispersion, high transmittance in the UV, visible, and IR

ranges, and resistance to thermal shock.

- Germanium (Ge):

- Composition: A semimetallic element with unique optical properties.

- Properties: High refractive index, excellent transmittance in the mid-to-far

IR range, and good mechanical strength.

Property- Optical Transparency: Both materials offer high transparency across a wide range of

wavelengths, making them suitable for various optical applications.

- Thermal Stability: Germanium, in particular, exhibits good thermal stability and

can withstand high temperatures without significant degradation.

- Resistance to Environmental Factors: Both materials are resistant to chemical corrosion and

mechanical stress, ensuring durability in harsh environments.

Function- Optical Window: Serves as a transparent barrier that protects sensitive optical

components while allowing light to pass through.

- Infrared Lens: Focuses and directs infrared radiation, enabling the capture and

analysis of thermal images.

- Combination: Combining CaF2 and germanium can optimize performance across a

broader spectral range, enhancing the lens's versatility.

Application- Thermal Imaging Cameras: Used in security, surveillance, and firefighting to detect heat

sources and monitor temperature changes.

- Scientific Research: Employed in spectroscopy, astronomy, and remote sensing to study

objects and phenomena across a range of wavelengths.

- Industrial Inspection: Utilized in non-destructive testing and quality control to

detect defects and measure temperature distributions in materials.

- Medical Imaging: Potentially used in thermal imaging systems for medical

diagnosis and treatment monitoring.

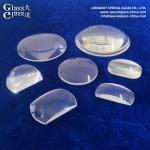

| Item | Optical Infrared Lens | | Material | Optical glass, Qurartz glass, Pyrex, borosilicate glass, Float

glass | | Diameter Tolerance | +0/-0.2 mm | | Thickness Tolerance | +/-0.2 mm | | Processed | by grinding, polishing | | Surface Quality | 80/50,60/40 | | Material Quality | no scratches and air bubble | | Transmission | above 90% | | Chamfer | 0.1-0.3 mm x 45 degree | | Surface Coating | Available | | Usage | Photography, Lighting system, Laser system |

|