Precision Fused Silica Quartz Glass Optical Window For Protective

Lens

The Precision Fused Silica Quartz Glass Optical Window For Protective

Lenss are specialized optical components designed to enhance the

performance and safety of laser cutting systems. Below is a

detailed description of their material, property, function, and

application: Material: - Quartz Glass: Both JGS1 and JGS2 lenses are made from quartz

glass, a material known for its high purity, low thermal expansion

coefficient, and excellent optical properties. Quartz glass is

particularly suited for high-energy laser applications due to its

high damage threshold and resistance to thermal stress.

Property: - High Purity: JGS1 and JGS2 quartz glass lenses are manufactured

with high purity levels, ensuring minimal absorption and scattering

of light, which is crucial for maintaining the quality of the laser

beam.

- Low Thermal Expansion: The low thermal expansion coefficient of

quartz glass helps to minimize thermal distortion and stress during

laser cutting operations, ensuring stable performance over extended

periods.

- Excellent Optical Transmission: Both JGS1 and JGS2 lenses offer

excellent optical transmission across a wide range of wavelengths,

making them ideal for use with various types of lasers.

Function: - Protective Lens: The primary function of these lenses is to

protect the laser cutting head and internal optics from damage

caused by debris, sparks, and other contaminants generated during

the cutting process.

- Beam Shaping: The lenses are also designed to shape and focus the

laser beam, ensuring precise and efficient cutting of materials.

- Energy Management: By absorbing and dissipating excess energy,

the lenses help to manage the intensity of the laser beam,

preventing damage to the workpiece and extending the lifespan of

the laser system.

Application: - Laser Cutting Systems: These lenses are specifically designed for

use in laser cutting systems, where they protect the laser cutting

head and internal optics from damage and help to shape and focus

the laser beam for precise cutting.

- High-Power Lasers: Due to their high damage threshold and

resistance to thermal stress, JGS1 and JGS2 quartz glass lenses are

particularly suited for use with high-power lasers, such as those

used in industrial and manufacturing applications.

- Precision Cutting: The excellent optical properties of these

lenses make them ideal for precision cutting applications, where

accuracy and repeatability are crucial.

In summary, the Precision Fused Silica Quartz Glass Optical Window For Protective

Lens are specialized optical components that offer a combination of

high purity, low thermal expansion, and excellent optical

properties. Their primary function is to protect the laser cutting

head and internal optics from damage and to shape and focus the

laser beam for precise cutting. These lenses are specifically

designed for use in laser cutting systems, particularly those

equipped with high-power lasers, and are well-suited for precision

cutting applications where accuracy and repeatability are

essential.

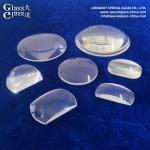

| Item | Optical Window lens | | Material | Optical glass, Qurartz glass, Pyrex, borosilicate glass, Float

glass | | Diameter Tolerance | +0/-0.2 mm | | Thickness Tolerance | +/-0.2 mm | | Processed | by grinding, polishing | | Surface Quality | 80/50,60/40 | | Material Quality | no scratches and air bubble | | Transmission | above 90% | | Chamfer | 0.1-0.3 mm x 45 degree | | Surface Coating | Available | | Usage | Photography, Lighting system, Laser system |

|