ISO9001 anodizing CNC machining aluminum parts service

|

|

In modern manufacturing, aluminum parts are widely used in aerospace, automotive manufacturing, consumer electronics, and other fields due to their lightweight, high strength, and excellent corrosion resistance. However, the processing and surface treatment requirements for aluminum parts are extremely high, and only professional services can ensure their performance and quality. The ISO9001 anodizing CNC machining aluminum parts service is designed to meet this demand. We are committed to providing customers with high-precision and high-quality aluminum parts processing and surface treatment solutions, helping your products stand out in the competition!

Why choose ISO9001 anodizing CNC machining aluminum parts service?

1. High precision manufacturing ensures perfect matching

2. Anodizing treatment to enhance performance and aesthetics

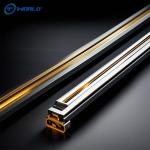

Anodizing is an advanced surface treatment technology that can significantly improve the corrosion resistance, wear resistance, and aesthetics of aluminum parts. Our anodizing process complies with international standards, ensuring that every product has excellent surface quality.

3. ISO9001 certification ensures quality assurance

We have passed the ISO9001 quality management system certification, and strictly follow international standards in every link from raw material procurement to production and processing, ensuring the high quality and consistency of our products.

4. Flexible customization to meet diverse needs

Whether you need individual parts or mass production, we can provide flexible customization services to meet your personalized needs.

Our advantages: professionalism, efficiency, and reliability

Application area: Meet the needs of multiple industries

Customization process: simple and efficient, worry free and effortless

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

| Product Tags: Anodized OEM CNC Machining Aluminum Parts ISO9001 CNC Machining Aluminum Parts OEM CNC Machining Aluminum Plastic Parts |

|

High-Performance CNC Machined Aluminum Parts for Modern Industrial Manufacturing |

|

CNC customized aluminum alloy material parts machining service |

|

Customized CNC Machining Services For Aluminum Alloy Material Parts |

|

CNC Lathe Parts Customized Aluminum Enclosure Parts for Electronic Devices |

|

Customized High-Precision CNC Machining Services Electronic Aluminum Alloy Parts |

|

Aluminum CNC Machining Parts Precision Sand Finish Aluminum Components |