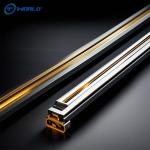

Custom Precision CNC Parts Metal Fabrications Aluminum CNC Machining Milling Turning Parts

|

|

Precision Black Anodizing Aluminum Accessories, Machined Aluminum Parts Quick details: 1. Keyword: CNC Aluminum Parts 2. Process: CNC Machining 3. Color: Black 4. Place of Origin: Guangdong, China 5. Application: Widely used 6. Drawing Format: 2D/(PDF/CAD)3D(IGES/STEP) 7. Equipment: CNC Machining Centers 8. Lead time: 1-2 weeks Specification:

FAQ: |

||||||||||||

| Product Tags: Custom Brushing Precision CNC Parts Brush Precision CNC Parts Aluminum CNC Machining Milling Turning Parts |

|

High-Performance CNC Machined Aluminum Parts for Modern Industrial Manufacturing |

|

CNC customized aluminum alloy material parts machining service |

|

Customized CNC Machining Services For Aluminum Alloy Material Parts |

|

CNC Lathe Parts Customized Aluminum Enclosure Parts for Electronic Devices |

|

Customized High-Precision CNC Machining Services Electronic Aluminum Alloy Parts |

|

Aluminum CNC Machining Parts Precision Sand Finish Aluminum Components |