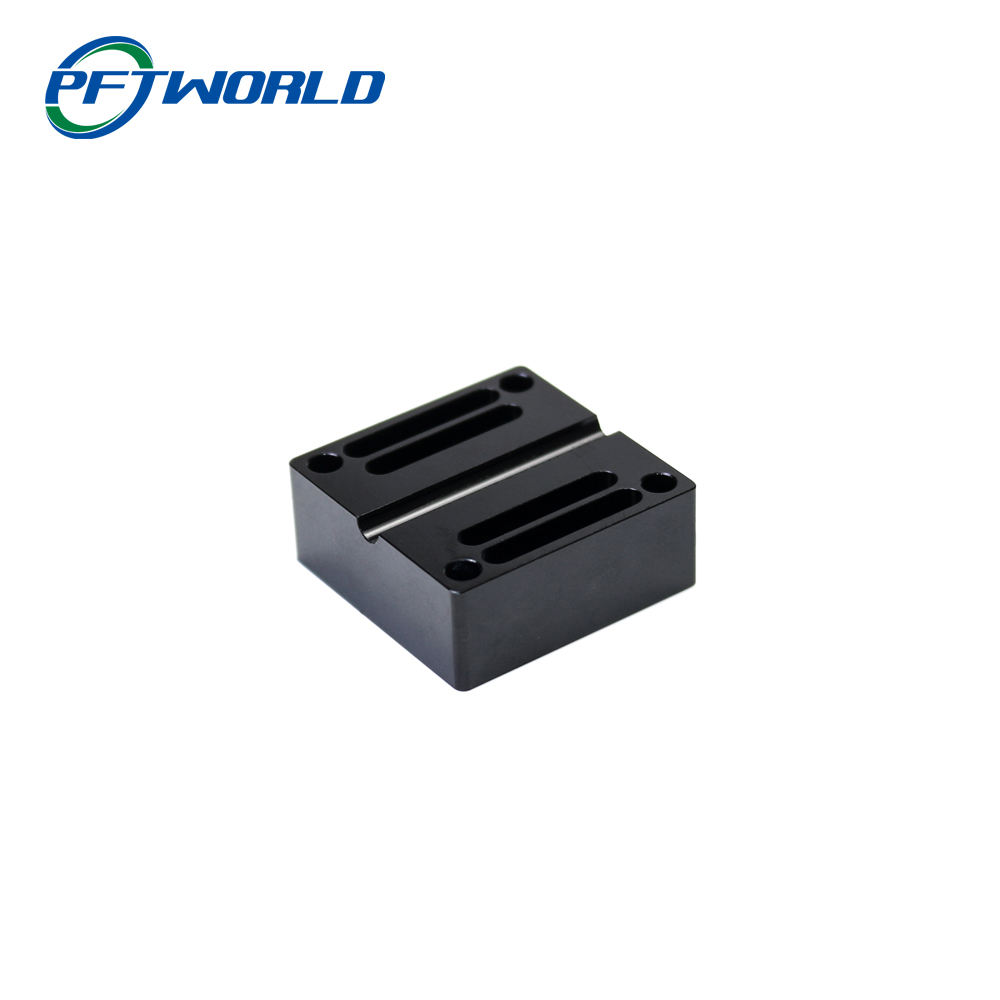

CNC machined aluminum black hardware

|

|

What Is CNC Machined Aluminum Black Hardware?

CNC machined aluminum black hardware refers to hardware components that are manufactured using Computer Numerical Control (CNC) technology. In this process, aluminum is precisely cut, shaped, and finished to create components that meet specific design requirements. The black finish is often achieved through anodizing or other surface treatment techniques, providing both an enhanced appearance and increased resistance to corrosion. CNC machining ensures high precision, tight tolerances, and excellent repeatability, making it ideal for applications where part quality and reliability are paramount. The black anodized aluminum finish not only gives hardware a sleek, modern look but also adds an extra layer of protection against environmental factors like moisture, heat, and abrasion.

Why Choose CNC Machined Aluminum Black Hardware?

This is particularly beneficial for hardware used in harsh conditions, such as outdoor equipment, automotive parts, or marine applications, where resistance to corrosion is essential for long-lasting performance.

2. Precision and Accuracy

For CNC machined aluminum black hardware, this precision extends to the surface finish as well. The black anodizing process is applied consistently, ensuring a uniform and smooth finish across all parts, which is vital for both aesthetics and performance.

3. Lightweight Yet Strong

When combined with the precision of CNC machining, aluminum parts can be produced with intricate designs without compromising strength. The black anodized finish further enhances the surface hardness, adding a layer of strength without increasing the part's overall weight.

4. Aesthetic Appeal

Additionally, the anodizing process allows for consistent coloring and texture, making CNC machined aluminum black hardware a perfect choice for high-end consumer products that require both function and style.

5. Customization and Versatility

Moreover, the black anodizing process can be tailored to meet specific aesthetic or functional requirements, with options for matte or glossy finishes, as well as the ability to add color and patterns if needed. Common Applications of CNC Machined Aluminum Black Hardware

1.Automotive Industry

2.Aerospace and Aviation

3.Electronics and Consumer Goods

4.Industrial Equipment

5.Medical Devices

ConclusionCNC machined aluminum black hardware offers the perfect combination of precision, strength, aesthetics, and durability. Whether used in automotive, aerospace, electronics, or industrial applications, these components provide exceptional performance and a sleek, modern look. The anodizing process enhances the material’s resistance to corrosion and wear, ensuring that the parts last longer and maintain their appearance in even the harshest environments.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

| Product Tags: Radiator CNC Machined Aluminum Parts Black Radiator CNC Machined Aluminum Parts CNC Machined Black Radiator Parts |

|

High-Performance CNC Machined Aluminum Parts for Modern Industrial Manufacturing |

|

CNC customized aluminum alloy material parts machining service |

|

Customized CNC Machining Services For Aluminum Alloy Material Parts |

|

CNC Lathe Parts Customized Aluminum Enclosure Parts for Electronic Devices |

|

Customized High-Precision CNC Machining Services Electronic Aluminum Alloy Parts |

|

Aluminum CNC Machining Parts Precision Sand Finish Aluminum Components |