OEM High Precision Injection Molded Plastic Parts

|

|

What Are OEM High Precision Injection Molded Plastic Parts?

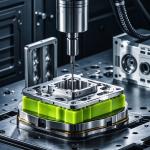

Injection molding is a manufacturing process in which molten plastic is injected into a mold under high pressure, allowing it to fill the mold and harden into the desired shape. This method is used to create a wide variety of parts with high precision, making it ideal for industries that demand exact dimensions and intricate features. OEM (Original Equipment Manufacturer) parts refer to components that are made to the specifications of a particular brand or product. OEM high precision injection molded plastic parts are custom-designed to fit seamlessly into your products, ensuring that each part works perfectly with your system. High precision in injection molding means that parts are produced with minimal deviation from the original design, offering excellent tolerances and uniformity. This is achieved through advanced molding techniques and high-tech machinery that guarantee superior consistency in mass production runs.

Benefits of OEM High Precision Injection Molded Plastic Parts

1.Unmatched Precision and Accuracy

2.Cost-Effective Mass Production

3.Complex Geometries and Intricate Designs

4.Consistent Quality Across Production Batches

5.Material Versatility

6.Rapid Prototyping and Fast Turnaround

Industries That Benefit from OEM High Precision Injection Molded Plastic Parts

2.Medical and Healthcare

3.Consumer Electronics

4.Industrial Equipment and Machinery

5.Aerospace and Defense

Conclusion

OEM high precision injection molded plastic parts offer a powerful combination of precision, efficiency, and versatility that makes them ideal for a wide range of industries. Whether you are working in automotive, medical, consumer electronics, or aerospace, the ability to create parts with high accuracy and cost-effectiveness ensures your components perform reliably and meet the highest standards. By choosing a trusted manufacturer with expertise in custom injection molding, you can ensure that your parts are produced to the highest quality, allowing you to stay competitive and meet the demands of your industry.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

| Product Tags: 0.001mm Injection Molded Plastic Parts High Pricision SLA 3D printed parts OEM SLA 3D printed parts |

|

High Durability Injection Molding Parts With Grinding / EDM / QC Processing |

|

Custom injection mold parts |

|

Customized Injection Molded Plastic Parts For Various Public Area Applications OEM |

|

Durability Public Area Injection Molded Plastic Parts For Airports And Hotels |

|

Processing plastic injection mold CNC parts |

|

CNC machining custom size injection plastic mold parts |