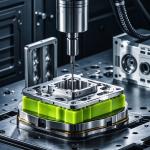

Precision Plastic Pipe, Injection Molding, Custom Nylon Accessories

Quick details:

1. Keyword: Injection Molding Parts

2. Process: Injection Molding

3. Color: Any

4. Place of Origin: Guangdong, China

5. Application: Any

6. Drawing Format: 2D/(PDF/CAD)3D(IGES/STEP)

7. Lead time: 1-2 weeks

Description:

Our company was founded in 2012 and is professional to do all kinds

of sheet metal fabrication manufacturers, industry involving

medical, electronics, furniture, auto parts, and other industries.

Our company has maintained quality first, reputation first,

inexpensive, and mutually beneficial business purposes. In recent

years, new and old customers' trust and support of the company's

performance is growing, we know that our achievements and

development from each customer's understanding and support of

friends. We believe that in the coming years, the company's

customers and all friends will continue to grow, and our technology

will continue to improve. We hope that through our services, create

more and better value for our customers and friends at the newer

and higher level.

Company Mission Statement

"Support our customers by providing innovative, cost-effective,

engineered solutions, prototypes, components, and assemblies,

enabling our respective business partners to achieve superior

financial results and quality growth."

Establish a challenging and enjoyable work environment to promote

teamwork.

Maintain our integrity with customers, suppliers, and employees.

Support our business partners, and exceed their expectations.

Be unified in our support and our pursuit of a unified vision.

Develop our people to be the best in the industry.

Specification:

| Material | Nylon |

| Application | Any |

| Color | Any |

| Package | Carton Box |

| Surface treatment | Testure/Sand/MT/YS/SPI/VDI |

| Drawing format | 2D/(PDF/CAD),3D(IGES/STEP) |

| Certificates | ISO9001:2015/ISO13485:2016 |

| Lead time | 1-2 weeks |

FAQ

Q1: Is your organization committed to the concept of total quality

management?

A1: Yes, no matter whether in laser cutting, bending, or CNC

machining, the workers will conduct the first sample inspection and

random inspection during the processing to ensure the quality of

the products.

Q2: How many checks are performed on a project?

A2: Usually, products will go through the following four

inspections: incoming inspection, production first inspection,

sampling inspection, and pre-shipment inspection. Among them,

sampling inspection will be conducted multiple times.

Q3: will you be able to work with our engineering team to review

drawings and provide quick, estimated pricing for desired changes?

A3: Yes, our engineers respond very quickly. If there is anything

to be modified in the product, we can offer you a new price as soon

as you tell us.

Q4: What kinds of information do you need for a quote?

A4: Kindly please provide the product drawing in PDF and will be

better if you can provide it in DWG/STP/IGS.