Custom injection molded housing

|

|

When it comes to designing a product, finding the right enclosure is often as crucial as the functionality of the product itself. Whether it's for electronics, industrial tools, medical devices, or consumer goods, the enclosure serves as the protective outer shell, safeguarding the internal components from environmental factors, physical damage, and even tampering. This is where custom injection molded enclosures shine, offering tailored solutions that combine durability, versatility, and precision.

What Are Custom Injection Molded Enclosures?

Why Choose Custom Injection Molding?

Whether your product needs to be compact, lightweight, or shock-resistant, custom injection molding allows for the freedom to create the ideal design. You can incorporate features like cable management, ventilation, mounting holes, or even sleek, modern finishes without compromising on durability.

2. Design Flexibility

The level of detail achievable through custom molding ensures your enclosure will meet both functional and aesthetic requirements.

3. Material Versatility

Selecting the right material is crucial to ensure the enclosure performs optimally in its intended environment. Custom injection molding allows you to choose the material that best suits your product’s needs, whether it's for outdoor, high-temperature, or electrical applications.

4. Cost Efficiency for High-Volume Production

Additionally, the automated nature of injection molding reduces the need for labor-intensive assembly, resulting in further cost savings.

5. Precision and Consistency

The repeatability of the injection molding process ensures that every batch of enclosures maintains the same high-quality standards, helping you maintain the integrity and performance of your product.

Applications of Custom Injection Molded Enclosures

The Process of Custom Injection Molding

Conclusion: Invest in Custom Injection Molded Enclosures for Optimal Results

If you're looking for a reliable, cost-effective, and high-quality enclosure solution, custom injection molding is the way to go. Let your product shine in a well-designed, durable, and perfectly engineered enclosure that will meet your exact needs and exceed your expectations.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

High Durability Injection Molding Parts With Grinding / EDM / QC Processing |

|

Custom injection mold parts |

|

Customized Injection Molded Plastic Parts For Various Public Area Applications OEM |

|

Durability Public Area Injection Molded Plastic Parts For Airports And Hotels |

|

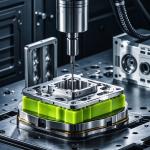

Processing plastic injection mold CNC parts |

|

CNC machining custom size injection plastic mold parts |