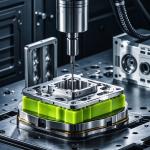

CNC machining of injection mold parts

|

|

What is CNC Machining of Injection Mold Parts?

CNC machining of injection mold parts refers to the use of Computer Numerical Control (CNC) technology to create the various components that make up injection molds. CNC machining involves using highly automated, computer-controlled tools to precisely cut, shape, and form metal or plastic parts. When applied to injection molds, it allows for the production of highly accurate, repeatable, and intricate features in mold components, ensuring that the injection molding process itself produces consistent and high-quality products. In injection molding, the mold acts as the blueprint for shaping the final product, making it essential for mold parts to be precise. CNC machining ensures that every detail—whether it’s cooling channels, cavity designs, or intricate contours—is fabricated with exacting standards.

Why CNC Machining is Essential for Injection Mold Parts

1.High Precision and Accuracy

2.Complex Geometries and Designs

3.Improved Quality and Consistency

4.Faster Prototyping and Production

5.Cost-Effective for Complex Parts

Applications of CNC Machining of Injection Mold Parts

The CNC Machining Process for Injection Mold Parts

2.Material Selection

3.CNC Machining

4.Inspection and Testing

5.Assembly and Final Adjustments

Conclusion

CNC machining of injection mold parts has revolutionized the manufacturing industry by enabling the production of high-precision, complex mold components that meet the rigorous standards of various industries. The combination of accuracy, efficiency, and design flexibility makes CNC machining an indispensable tool for manufacturers looking to produce top-quality injection molds and molded products. If you're looking to streamline your production process and improve the quality of your molded parts, partnering with an experienced CNC machining provider for your injection mold needs is a smart investment. With the right technology and expertise, CNC machining ensures that every mold component is crafted to perfection, resulting in superior performance, reduced costs, and faster time-to-market.

FAQ1. Are you a manufacturer or a trading company? We are a factory located in Shenzhen, China, with 20 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. 2. How to get a quote? Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information. 3. Can I get a quotation without drawings? Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. 4. Can you provide samples before mass production? Of course, the sample fee is necessary. If possible, it will be returned during mass production. 5. What is the delivery date? Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks. 6. How do you control quality? (1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. 7. After sales service team If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

|

|

High Durability Injection Molding Parts With Grinding / EDM / QC Processing |

|

Custom injection mold parts |

|

Customized Injection Molded Plastic Parts For Various Public Area Applications OEM |

|

Durability Public Area Injection Molded Plastic Parts For Airports And Hotels |

|

Processing plastic injection mold CNC parts |

|

CNC machining custom size injection plastic mold parts |