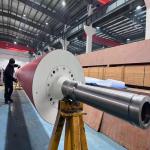

Biaxially Oriented Plastics Film Line MDO Nip Roller Silicon Rubber Coated Rollers

|

|

Biaxially Oriented Plastics Film Line MDO Nip Roller Silicon Rubber Coated

MDO Nip Roller Basis Information

Biaxially Oriented Plastics Film (BOPF), referred to as BOPF, is a general term for plastic films made by biaxial stretching (or biaxial orientation). It is by physical, chemical, mechanical and other means of special molding processing. It is the longitudinal and transverse bidirectional stretching of thick film or flat film at a temperature lower than the melting point of the film and higher than the glass transition temperature. Then the product is obtained by heat setting treatment in a tense state.

The MDO stretching process of biaxially oriented plastic film production line (BOPP, BOPET and other materials) is a crucial link in its production process, which directly affects the physical properties of the film and the quality of the final product.

MDO Nip Roller Features

Surface Quality: The nip Rollers have a flat, smooth, centered, and round surface to ensure continuous sealing against each other.

Durometer: The covering on the Rubber Roller is designed to be soft, allowing it to conform well to the film passing between the rollers, especially folded edges or gusseted films.

Trapping Air: The nip rollers are designed to trap air inside the bubble of the film, especially in conventional non-IBC air ring cooling systems.

Roller Repair: If the rubber roller's surface becomes worn or damaged, it can be repaired by regrinding or recovering, although this may result in substantial downtime on the production line.

MDO Nip Rller Benefits

Consistent Speed: The primary nip rollers in the blown-film process ensure a consistent speed, which directly affects film quality and profitability.

Bubble Stability: By trapping air inside the bubble, the nip rollers help maintain bubble stability during the film production process.

Film Quality: The flat and smooth surface of the nip rollers prevents defects such as creasing or film damage caused by crushing the folds.

Uniform Pressure: The nip rollers apply uniform pressure across the film, ensuring consistent and equal roll speed and uniform pressure between the rollers.

Defect Detection: The use of nip impression films, such as Fujifilm Prescale, can help diagnose issues related to roller alignment, parallelism, and pressure load distribution.

Huatao understands that each customer may have different requirements, which cannot meet from one factory, but we can meet, we are also familar with domestic factory advantages with matching superior quality and help customer not walk bend road.

We pursue each customer is buying and using HUATAO products with a rest assured heart and service is never end.

|

||||||||

| Product Tags: MDO Nip Roller Plastics Film Line Nip Roller Silicon Rubber Nip Roller |

|

|

Ozone Resistant Liquid Silicone Roller RTV Anti Stick For PP / PE / PVA / PVC Film |

|

High Temperature Resistance Spreader Roll with Black Color |

|

Rubber Covered Spreader Roll High Temperature Resistance Abrasion Proof |

|

Imported High Temperature Resistant MDO Nip Roller Good Resilience |

|

BOPP BOPET Film Line EPDM Corona Nip Roller With Excellent Aging Resistance |

|

Uniform Corona Discharge Corona Roller Increase Plastic Film Surface Roughness |