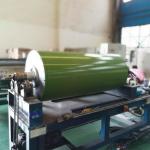

High Thermal Efficiency Heating Calender Roll For Non Woven Line

|

|

High Thermal Efficiency Heating Calender Roll For Non-woven Line

Non-woven Heating Calender Roll material:

All high-quality alloy steel (38CrMOa i, 42CrMo, 60CrMo, 9Cr2Mo) is used as the base material, and is formed by mechanical processing and heat treatment. Surface hardness HRC58~62.

Non-woven Heating Calender Roll Heating method:

Hollow inner liner spiral heating:

Drill deep holes in the forging, install spiral liner or spray liner in the middle space, so that the heat transfer oil flows (or sprays) in a directional manner in the spiral liner to achieve the purpose of heating. Temperature difference ≤1.5°C.

Peripheral drilling heating:

Drill deep holes evenly around the roller body to make the heat transfer oil circulate and flow in the peripheral holes for heating, with a smaller temperature difference (<1°C) and higher thermal efficiency.

Non-woven Heating Calender Roll Pattern:

It can be engraved into any regular and irregular patterns such as square dots, round dots, elliptical dots, diamond shapes, cross shapes, stripes, etc. according to user needs. ● After quenching and engraving, the hardness layer is > 5mm, while the hardness layer of the original hot rolling roller using nitriding process is only 0.4~0.5mm; ● The size and depth of the rolling point remain basically unchanged after long-term use. ● Greater advantages: correct pattern, optional pattern, depth and angle;

Synchronized with the quality of European hot rolling rollers.

About us

Huatao understands that each customer may have different requirements, which cannot meet from one factory, but we can meet, we are also familar with domestic factory advantages with matching superior quality and help customer not walk bend road.

We pursue each customer is buying and using HUATAO products with a rest assured heart and service is never end.

|

||||||||||||

| Product Tags: heating calender roll Non woven Line Calender Roll High Thermal calendar roller |

|

Low Energy Consumption Teflok Coating Electromagnetic Induction Heating Roller Film Lamination |

|

100-150um Chrome Coated MDO Preheating Roller RPM 800M/MIN |

|

Ultra Precision Electromagnetic Induction Heating Calender Roller Battery FCCL Temperature Control Accurancy |

|

High Temperature Resistant Teflok MDO Preheating Roller Anti Sticky |

|

135 Celsius Degree Resistant SCE MDO Stretching Roller 700MPM |

|

Hard Chrome Plating Electromagnetic Induction Heating Calender Roller Nonwoven Fabric Uniform Surface Temperature Distribution |