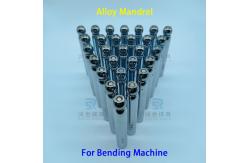

Customizable Alloy Mandrel for CNC 3D Tube Bender High-Strength Tube Bending

|

|

Alloy Mandrel Description:

Durable Alloy Mandrel for High-Strength Tube Bending:Made from imported SUJ2 bearing steel and a super-hard alloy ball head, this alloy mandrel provides exceptional wear resistance and strength for bending stainless steel and iron tubes. It is designed for use with CNC pipe bending machines and is ideal for industries such as heat exchangers, automotive tube fittings, and furniture. The mandrel ensures smooth, precise bends and has a long service life. It is capable of bending tubes with diameters such as Φ9.52, Φ12, Φ12.7, Φ15.88, Φ16, and Φ19.05, with custom sizes available.

Alloy Mandrel Specifications:

Application Industry:

Manufacturing Workshop:

FAQ Q:What is the name of this product? A:Bending Mandrel One-Way Mandrel Dull Mandrel Alloy Mandrel Aluminum tube mandrel Q: Are you trading company or manufacturer ? A: We are manufacturer. Q: What industry is the Alloy Mandrel mainly used for? A: It is an important bending tube parts for CNC 3D tube bending machine and copper tube hairpin bender or return bender Q: How to manufacture after the order is confirmed? A: We need to provide samples or drawings, one of which is sufficient. Our production engineers are professionals with over 10 years of experience, and they know how to control tolerances and precision. Q: How long is your delivery time? A: Generally it is 5-10 working days if the goods are in stock. or it is 10-25 working days if the goods are not in stock, it is according to quantity. Q: What is your terms of payment ? A: Payment<=10000USD, 100% in advance. Payment>10000USD, 50% T/T in advance ,balance before shippment. If you have another question, pls feel free to contact us

|

|

Efficient 4 Jaw Chuck For Φ60 Copper Tube Production Machinery |

|

5mm 3 Jaw Chuck For Hole Punching And Copper Tube Bender Machine |

|

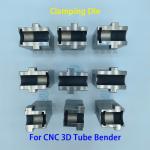

Φ14mm Clamping Die For CNC End Forming And Tube Bender Integrated Machine |

|

Custom POM Material Clamping Die to Prevent Copper Tube From Being Scratched |

|

Alloy Mandrel for Bending of Stainless Steel Tube in Heat Exchanger Production |

|

Alloy Mandrel For Steel And Iron Tubes Precision Bending On CNC Machines |