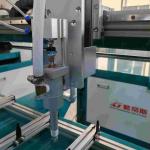

500mm/sec Adhesive Dispensing Robots Intelligent Industrial Glue Dispenser 700*650*1200mm

|

|

Intelligent Glue Dispensing Robot System for LED Panel Light Sealing process

Machine Description

The glue dispensing robot is an advanced automation solution specifically designed for panel light manufacturing, delivering precision and efficiency in silicone adhesive application. This system integrates PLC controls, multi-axis robotic arms to handle various panel light sizes (e.g., 600×600mm, 1200×600mm) and complex geometries with exceptional accuracy (±0.1mm). It ensures uniform glue dispensing for critical functions such as waterproofing, dustproofing, and structural integrity, meeting IP67 standards. Equipped with optimized dispensing algorithms, the glue dispensing robot minimizes material waste while supporting fast-curing silicones. Its programmable settings allow precise control over dispensing speed and volume, making it ideal for smart factory integration. By enhancing throughput, reducing manual intervention, and ensuring repeatability, this system significantly boosts productivity in large-scale panel light production. Furthermore, it supports sustainable manufacturing practices by improving resource efficiency and reducing operational costs, making it a vital tool for modern LED lighting industries.

Machine Features

Technical Parameters

Machine Details

|

||||||||||||||||||||||||

| Product Tags: 500mm/sec Adhesive Dispensing Robots Adhesive Dispensing Robots Intelligent Industrial Glue Dispenser 700*650*1200mm |

|

220V Glue Dispensing Robot 3 Axis Robotic Adhesive Dispenser 700*650*1200mm |

|

Multi Function Adhesive Dispensers 3 Axis Gluing Dispenser 1500*600*100mm |

|

Six Heads Glue Dispensing Robot 50Hz - 60Hz Automated Glue Dispenser For Back Lit Panel Light |

|

Customized Automatic Glue Dispenser Machine CE Approved Dispensing Systems |

|

150W Glue Dispensing Robot 8 Heads Adhesives Dispenser 220V For 2x4 Back Lit Panel Light |

|

3 Axis Robotic Dispenser 2200*800*1200mm Industrial Glue Dispensers 500mm/sec |