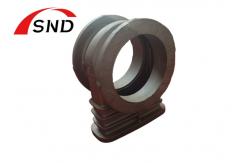

WC6 WC9 Valve Body Casting High Temperature Alloy Steel Castings Output

|

WC6 WC9 Valve Body Casting High Temperature Alloy Steel Castings Output

Product Description:

Our WC6 and WC9 valve body castings are high - quality high - temperature alloy steel castings. Conforming to strict industry standards, they are engineered to endure extreme temperatures, making them ideal for high - temperature applications such as in power plants and chemical refineries. The WC6 and WC9 alloys provide excellent mechanical properties, including high strength and good creep resistance at elevated temperatures. Our advanced production techniques ensure precise dimensions and reliable quality of these castings. With a stable output, we can meet large - scale orders, offering reliable solutions for your high - temperature valve needs.

Advantages of castings:

1. High high - temperature strength: It can maintain high strength in high - temperature environments and is not prone to deformation and damage. 2. Good oxidation resistance: It can effectively resist oxidation at high temperatures, extending the service life of the material. 3. Excellent creep resistance: It can maintain stable shape and dimensions under long - term high - temperature and stress conditions. 4. Strong thermal stability: When the temperature changes, the performance of the material fluctuates little, ensuring stable operation. 5. Superior welding performance: It is easy to be welded,

facilitating the manufacture of complex components. SND FOUNDRY have been specializing in the production and sales

of metal casting products nearly 20 years. SND has fully passed the ISO9001 quality management system certification. During the production process, it implements a number of strict detailed standards and conducts full-process quality control. Our company has well-equipped chemical laboratories and physical performance laboratories. A complete set of testing equipment such as Direct Reading Spectrometer, Metallographic Microscope, Hardness Tester, Universal Material Testing Machine and Pressure test machine can be used to effectively control chemical composition and ensure mechanical performance.

FAQ: Q: Are you a factory or trading company? A:We're a direct factory,we have our own casting foundry and

machining factory over 20 years. Q: Do you make customized products based on our design drawings? A: Yes, we are a professional metal fabrication factory with 20

experiences to make custom products according to clients' drawings. Q: Will my drawing be safe after you get it? A: Yes, we will not release your design to third party unless with

your permission. Q: What is the MOQ? A: Usually we don't set MOQ, but the more, the cheaper. Besides, we

are happy to make prototype or sample for clients to ensure quality standard. Q: Whether some samples can be provided? A: Yes, just need some sample cost and express cost,we will provide

some parts which we have stock. Q: How fast can my samples be finished? A: Generally 5-7 Working days

|

||||||||||||||||||||||||||||||||

| Product Tags: WC6 Valve Body Casting WC9 Valve Body Casting Alloy Steel wc6 valve body | ||||||||||||||||||||||||||||||||

|

Custom CNC Machining Precision Steel Casting Service Metal Tooling Auto Parts |

|

WC6 WC9 Valve Body Casting High Temperature Alloy Steel Castings Output |

|

Sand Casting Parts For Valve Part Alloy Steel Casting High Precision Castings |

|

Cast Steel Casting Accessories For Valve Parts Precision Casting |

|

Custom Investment Casting Or Lost Wax Casting Steel Casting Parts As Drawing |

|

Cast Steel Castings Valve Housing And Fittings For Valve Castings Valve Part |