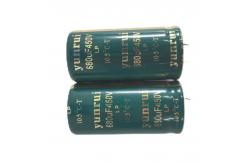

Features:

Rated Capacitance: 680μF

Rated Voltage: 450V DC

Operating Temperature: -40°C ~ +105°C

Endurance: 2000 ~ 5000 hours @105°C

Leakage Current: ≤ Specified value

ESR: Low ESR design (suitable for power supply filtering)

Pins: Radial type (2-pin, snap-in optional)

RoHS Compliant: Yes

Applications:

Power Supply Units (PSU)

LED Driver Power Boards

Industrial Equipment

Inverter Systems

Energy Storage Modules

Home Appliances

Advantages:

Long-life 105°C design

High ripple current resistance

Stable performance in high-voltage environments

OEM/ODM support available

Matters needing attention

Notes for using aluminum electrolytic capacitors

(1) DC aluminum electrolytic capacitor should be used according to

the correct polarity When the DC aluminum electrolytic capacitor is

connected to the circuit according to the reverse polarity, the

capacitor will short circuit, and the resulting current will cause

damage to the capacitor. If it is possible to apply a positive

voltage to the negative lead, select the nonpolar product.

(2) Use it below the rated working voltage When the applied voltage

on the capacitor is higher than the rated working voltage, the

leakage current of the capacitor will rise and its electrical

characteristics will deteriorate in a short time until damage. Note

that the peak voltage does not exceed the rated working voltage.

(3) Rapid charge and discharge use When conventional capacitors are

used for rapid charging, their service life may be reduced by

falling capacity, sharp temperature rises, etc.

(4) Storage of the capacitor When the aluminum electrolytic

capacitor is stored for a long time, the leakage current usually

increases, the higher the storage temperature, the faster the

leakage current rises, the longer the storage time, the higher the

leakage current value. Therefore, attention should be paid to the

storage environment and time. After the voltage is applied to the

capacitor, the leakage current value will drop continuously. If the

rise of the leakage current value of the aluminum electrolytic

capacitor has a bad effect on the circuit, please charge it before

use.

(5) The applied ripple current should be less than the rated value

When the applied ripple current exceeds the rated value, the

capacitor temperature will rise to be too high, the capacity will

decrease, and the impedance will increase (DF increases) will

shorten. The peak value of the applied ripple voltage shall be less

than the rated operating voltage.

(6) Use of the ambient temperature The service life of aluminum

electrolytic capacitors is affect by the ambient temperature.

According to scientific statistics, the use of ambient temperature

decreased by 20℃ its service life increased by 10 times.

(7) Lead line strength When a tensile force is applied to the

capacitor lead line, the tension will act inside the capacitor,

which may cause a short circuit, open circuit or rising leakage

current.weld the capacitor to the circuit board, do not shake the

capacitor strongly.

(8) Heat resistance during the welding process When the solid

polymer capacitor is loaded into the circuit board for immersion

welding or wave welding, the product body may degrade the polymer

layer and increase the leakage due to the long welding time and

high temperature.

(9) The installation hole distance and the installation position of

the circuit board The design of the mounting hole of the circuit

board shall be consistent with the lead pin distance in the product

specification. If the capacitor is forced into the circuit board

with unmatched hole distance, there will be stress on the lead

line, which may lead to short circuit or leakage current rise.

(10) About the cleaning after welding

① Capacitors cannot be cleaned with halogenated organic matter

series of cleaning agents. If cleaning is necessary, use a cleaning

agent that guarantees the capacitor quality. ② For the cleaning

agent that can ensure the quality of capacitors,please do not keep

it in the cleaning solution or sealed container after cleaning.

After cleaning, please dry with the circuit board in the hot air

for more than 10 minutes, and the temperature of the hot air should

not be higher than the upper limit of the capacitor.

(11) About fixative and coating (coating agent)

① Please do not use fixatives and coatings (coatings) containing

halogenated organic matter series. ② Please do not allow the

fixative and coating (coating agent) to seal the capacitor seal

part (terminal side).