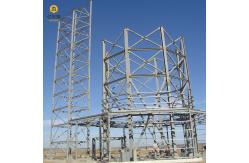

Prefabricated Steel Structure Metallic building Warehouse

Workshop

Steel structure design common norms are as follows:

" Steel Design Code" (GB50017-2003)

" Cold-formed steel structure technical specifications"

(GB50018-2002)

" Construction Quality Acceptance of Steel" (GB50205-2001)

" Technical Specification for welded steel structure" (JGJ81-2002,

J218-2002)

" Technical Specification for Steel Structures of Tall Buildings"

(JGJ99-98)

The factory steel structure/prefabricated steel structure/steel

frame structure building is an pre-engineered steel structure which

is widely used for large-scale workshop, or used for the warehouse,

supermarkets, entertainment centers and other buildings.

| Name | Steel structuree | | Dimensions | Length | H beam: 4000-15000mm | | Thickness: | web plate: 6-32mm

wing plate: 6-40mm | | Height | 200-1200mm | | Color | According to customers | | Size | MOQ is 300 m2, width * length * eave height, | | Advantages | 1. Lower cost but beautiful outlook.

2. High safety performance.

3. easy to assemble and dismantle

4. manufacture under complete quality control system---ISO9001

5. installation with instruction of experienced engineers

6. Non-pollution. | | Main components | Base | Cement and steel foundation bolts | | Main frame | H beam | | Material | Q235B, Q345B or others as buyers' requests. | | Purlin | C or Z purlin: Size from C120~C320, Z100~Z20 | | Bracing | X-type or other type bracing made from angle, round pipe | | Bolt | Plain bolt and High-strenth bolt | | Roof & wall | Sandwich panel or color plate | | Door | Sliding or rolling door | | Window | Aluminium alloy window | | Surface | Two lays of Anti-rust Painting or Hot Dip Galvanized | | Sheet | 0.5mm or 0.6mm galvanized sheet | | Accessories | Semi-transparent skylight belts, Ventilators,

down pipe, Glavanized gutter, etc | | Usages | 1. workshop, warehouse, plant

2. Steel web frame structure

3. Steel H-column and steel H-beam

4. Portal frame products

5. High rise building project

6. Others steel structure buildings | | Packing | Main steel frame without packing load in 40' OT,

roof and wall panel load in 40' HQ! | | Drawing: | According to drawings or according to customer ' s requirement. |

Design Parameters | If you need we design for you, please supply us the following

parameter

together with detail size:

1) length, width, height, eave height, roof pitch, etc

2) wind load, snow load, raining condition, aseismatic

requirements, etc

4) Demands for doors and windows

5)Other information if necessary |

Main steel structure

(columns and beams) | 1.Steel Q345(S355JR) or Q235(S235JR)H shape

2. Straight cross-section or Variable cross-section | | Sub steel structure | 1.Material Q235(S235JR) steel

2.Bolt connections. Anti-rust painted or galvanized

3. Bracing:X-type or V-type or other type bracing made from angle,

round pipe, etc

4. Purlin:C or Z type: Size from C80~C320, Z120~Z300 | | Roof | Sandwich panel(PU/EPS/fiberglass/rook wool) or Colorful steel tile | | Wall | Sandwich panel(PU/EPS/fiberglass/rook wool) or Colorful steel tile | | Doors | Steel rolling shutter or others | | Windows | Alu. Alloy window,or others | | Edge Cover | Steel sheet 0.5mm thickness | | Bolts | M24,M22,M16 embedded bolts,intensive bolts,galvanized ordinary

bolts,high-strength bolts, etc | | Others options | Skylight panel,Roof ventilator,Down pipe,Galvanized,Crane,sanitary

Products | | Foundation | Cement and steel foundation bolts |

Packing and loading Shipment via 20'/40'/40HC/40OT sea containers

*All steel structure weld components are carefully packed with

blankets or bubble wrap to prevent scratches during loading and

unloading.

*All steel structures components are consolidated in steel pallets within the container, optimizing

loading and unloading time and labor costs.

*All sandwich panels are efficiently packed in steel pallets.

*Comprehensive container load plans and regional unloading plans

are devised to avoid onsite retransportation.

|